24 X 36 Commercial Work Table: A Comprehensive Guide

A 24 x 36 commercial work table is a ubiquitous piece of equipment found in a wide range of industries, from food service and healthcare to manufacturing and warehousing. These tables provide a durable and versatile surface for various tasks, contributing significantly to operational efficiency and workplace safety. The dimensions, 24 inches in depth and 36 inches in width, offer a practical balance between ample workspace and efficient utilization of floor space. This article delves into the key features, benefits, applications, and considerations when selecting a 24 x 36 commercial work table.

Durability and Construction Materials

The durability of a commercial work table is paramount, especially in demanding environments. The most common material used in the construction of these tables is stainless steel. Stainless steel offers exceptional resistance to corrosion, staining, and impact, making it ideal for applications where hygiene is critical and frequent cleaning is necessary. Different grades of stainless steel are available, with 304 stainless steel being a popular choice due to its balance of durability and cost-effectiveness. For applications requiring even greater resistance to harsh chemicals or extreme temperatures, 316 stainless steel may be considered. The gauge (thickness) of the stainless steel also plays a crucial role in determining the table's load-bearing capacity and overall robustness. Thicker gauges offer greater strength and resistance to bending or warping under heavy loads. In addition to stainless steel, some commercial work tables may feature galvanized steel or aluminum frames for structural support. These materials offer a lighter weight alternative while still providing adequate strength. The quality of welds and joinery is also critical to the table's overall durability. Properly executed welds ensure a seamless and strong connection between different components, preventing premature failure and enhancing the table's lifespan.

The frame, often constructed from steel or aluminum, provides the foundational support. The design of the frame can vary, from simple leg structures to more complex designs incorporating cross bracing or adjustable feet. Cross bracing provides added stability, particularly in applications where the table is subjected to significant lateral forces. Adjustable feet are essential for leveling the table on uneven surfaces, ensuring a stable and safe work environment. Some work tables also include built-in shelving or drawers, adding to their functionality and storage capacity. These features are typically constructed from the same materials as the tabletop and frame, maintaining consistency in durability and hygiene.

Applications Across Industries

The versatility of a 24 x 36 commercial work table makes it suitable for a diverse array of applications across various industries. In the food service industry, these tables are indispensable for food preparation, plating, and packaging. Their stainless steel construction ensures compliance with stringent hygiene standards, preventing contamination and facilitating easy cleaning. Restaurants, cafes, bakeries, and catering services all rely on these tables for their daily operations. The convenient size allows for efficient workflow in even the most cramped kitchen environments. Bakeries often utilize these tables for kneading dough and preparing pastries. Catering services find them useful for assembling and packaging food for delivery or events.

In the healthcare sector, these tables serve as vital surfaces for preparing medical supplies, organizing equipment, and conducting minor procedures. Hospitals, clinics, laboratories, and pharmacies all benefit from the hygienic and durable nature of stainless steel work tables. Their easy-to-clean surfaces help maintain a sterile environment, minimizing the risk of infection. Pharmacies utilize them for compounding medications and preparing prescriptions. Laboratories use them for conducting experiments and analyzing samples. Hospitals employ them for preparing surgical instruments and organizing patient care supplies.

Manufacturing facilities utilize these tables for assembly, inspection, and packaging processes. Their robust construction can withstand the demands of heavy tools and materials. The smooth, flat surface provides a stable platform for precision work. Automotive manufacturers, electronics manufacturers, and aerospace companies all employ these tables in their production lines. Warehousing and distribution centers use these tables for sorting, labeling, and packing goods. Their durability and ease of maintenance make them ideal for handling a high volume of packages and materials. The 24 x 36 dimension is conducive to individual workstations dedicated to specific tasks.

Key Considerations When Selecting a Table

Choosing the right 24 x 36 commercial work table requires careful consideration of several factors. The intended application is the first and most important consideration. The type of tasks the table will be used for will dictate the required features, materials, and dimensions. For example, a table used for cutting meat in a butcher shop will require a thicker gauge stainless steel and a built-in cutting board, whereas a table used for assembling electronics may benefit from an ESD (electrostatic discharge) surface to protect sensitive components.

The load-bearing capacity of the table is another critical factor. It is essential to select a table that can safely support the weight of the items that will be placed on it. Overloading a table can lead to structural damage and potential safety hazards. Manufacturers typically provide load capacity ratings for their tables, which should be carefully reviewed before making a purchase. The gauge of the stainless steel or other materials used in the construction of the table directly impacts its load-bearing capacity. Thicker gauges generally offer greater strength and can support heavier loads.

Hygiene and ease of cleaning are paramount, especially in food service and healthcare environments. Stainless steel tables are generally the preferred choice due to their non-porous surface and resistance to bacteria growth. Look for tables with rounded corners and smooth surfaces to minimize the accumulation of dirt and debris. The design should facilitate easy wiping and sanitizing. Some tables may feature adjustable feet that allow for easy cleaning underneath the table. The ability to quickly and efficiently clean the work surface is critical for maintaining a sanitary and safe work environment.

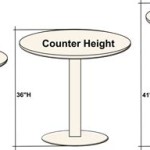

The presence and type of additional features can also influence the selection process. Shelves, drawers, or under shelves provide additional storage space for tools, supplies, and equipment. Tables with adjustable height settings offer ergonomic benefits, allowing users to customize the table to their preferred working height. Casters (wheels) can provide mobility, allowing the table to be easily moved around the workspace. Tables with edges or backsplashes can help prevent spills and contain materials on the work surface. The inclusion of these features should be based on a careful assessment of the specific needs of the application. Choosing a table with unnecessary features can increase the cost without providing any tangible benefits.

Budget constraints also play a significant role in the selection process. Commercial work tables range in price depending on the materials used, construction quality, and features included. Prioritize the most essential features based on the intended application and select a table that offers the best value for the available budget. It is often more cost-effective to invest in a higher quality table that will last longer and require less maintenance over time. Consider the long-term cost of ownership, including potential repair or replacement costs, when making a purchase decision. Researching different brands and comparing prices can help ensure that you are getting the best deal possible.

Finally, compliance with relevant industry standards and regulations should be verified. In the food service industry, tables should comply with NSF (National Sanitation Foundation) standards, ensuring that they meet stringent hygiene requirements. In the healthcare sector, tables should comply with relevant health and safety regulations. Confirming compliance with these standards provides assurance that the table is safe and suitable for its intended application. Failure to comply with these standards can result in fines, penalties, or even closure of the business.

Maintenance and Care

Proper maintenance and care are essential for extending the lifespan of a 24 x 36 commercial work table and maintaining its hygienic properties. Regular cleaning is crucial, especially in environments where the table is exposed to food, chemicals, or other contaminants. After each use, the table should be wiped down with a mild detergent and warm water. For more stubborn stains or spills, a stronger cleaning solution may be required. However, avoid using abrasive cleaners or scouring pads, as these can scratch or damage the surface. For stainless steel tables, a stainless steel cleaner can be used to remove fingerprints and maintain a shiny appearance.

Periodic disinfection is also recommended, particularly in healthcare settings or food preparation areas. Use a disinfectant solution that is approved for use on food contact surfaces and follow the manufacturer's instructions carefully. Ensure that the table is thoroughly rinsed and dried after disinfection to prevent the buildup of chemical residues. Regularly inspect the table for any signs of damage, such as dents, scratches, or rust. Repair any damage promptly to prevent it from worsening and compromising the table's structural integrity.

The legs and feet of the table should also be inspected regularly and tightened or adjusted as needed. Loose or uneven legs can create instability and pose a safety hazard. Lubricate moving parts, such as casters or drawer slides, to ensure smooth operation. By following a regular maintenance schedule, you can maximize the lifespan of your 24 x 36 commercial work table and ensure that it continues to provide a safe and efficient work surface.

Regency 24 X 36 16 Gauge 304 Stainless Steel Commercial Open Base Work Table

24 X 36 18 Gauge 304 Stainless Steel Commercial Work Table With Cast Koolmore

Regency Stainless Steel Worktable W Backsplash 24 X 36

Regency 24 X 36 18 Gauge 304 Stainless Steel Commercial Work Table With Galvanized Legs Undershelf And Casters

Vevor Stainless Steel Prep Table 24 X 18 36 In Commercial Workstation With Adjustable Undershelf Kitchen Silver J24x18x36inchuft3v0 The Home Depot

Gymax 24 X 36 Stainless Steel Commercial Kitchen Work Table W 4 Wheels Com

Vevor Commercial Worktable Workstation 24 X 36 Inch Food Prep With 2 Drawers Undershelf And Backsplash 992 Lbs Load Stainless Steel Kitchen Island For Restaurant Home Hotel Com

Regency 24 X 36 18 Gauge 304 Stainless Steel Commercial Work Table With 4 Backsplash Galvanized Legs Undershelf And Casters

Costway 24 X 36 Stainless Food Prep Work Table Commercial Kitchen Worktable

24 X 36 18 Gauge 304 Stainless Steel Commercial Work Table With Cast Koolmore