Making Leaves for a Table: A Comprehensive Guide

Extending a dining table's surface area is a common need, particularly when hosting gatherings. A well-crafted table leaf seamlessly integrates with the existing structure, providing additional space without compromising the table's aesthetic appeal or structural integrity. This article provides a detailed guide on crafting table leaves, covering essential considerations, material selection, the construction process, and finishing techniques.

Before embarking on the construction process, several factors must be meticulously considered. Ignoring these preliminary steps can lead to leaves that fit poorly, lack structural stability, or clash aesthetically with the original table. These considerations encompass the type of extension mechanism, the required size and number of leaves, and the grain orientation of the wood.

Understanding Extension Mechanisms

The existing extension mechanism of the table heavily influences the design and construction of the leaves. Common mechanisms include drop-leaf, butterfly leaf, and expanding table slides. Each mechanism necessitates a specific approach to leaf construction and attachment.

Drop-Leaf Tables: These tables feature hinged leaves that fold down along the sides. Constructing a drop-leaf requires precise hinge placement and a support system, such as gate legs or folding brackets, to hold the leaf in the extended position. The wood grain must align seamlessly with the table's edge when the leaf is unfolded.

Butterfly Leaf Tables: A butterfly leaf is a single leaf that folds in half and stores beneath the tabletop. When needed, it unfolds and pivots into place. Construction involves creating a hinged center section and ensuring the leaf fits snugly within the table's cavity when folded. Accuracy in measurements and hinge placement is crucial for proper functionality.

Expanding Table Slides: These tables utilize a system of interlocking wooden or metal slides that pull apart, creating a gap into which leaves are inserted. This type requires careful consideration of the leaf's thickness and edge profile to ensure a flush fit with the existing tabletop when extended. The leaves must also be designed to sit securely on the extended slides without wobbling or sagging.

The specific mechanism dictated by the original table dictates the fundamental design parameters for the leaves. Deviation from these parameters will likely result in an unusable extension.

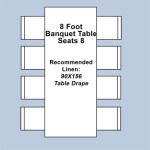

Deciding on the size and number of leaves is dictated by the anticipated need for additional seating or surface area. Consider the maximum number of guests typically hosted and the amount of space required per person. The size of each leaf should be manageable for storage and handling. Furthermore, the cumulative weight of multiple leaves should be considered to ensure the table's structural integrity, especially when using expanding table slides.

Matching the existing wood species and grain orientation of the table is crucial for visual harmony. Selecting wood with similar color and figuring will minimize the contrast between the original tabletop and the leaves. Paying attention to grain direction is essential; the grain should flow seamlessly from the tabletop to the leaves when the table is extended. Employing proper techniques such as bookmatching or slip matching can enhance the visual integration of the leaves with the table.

Once the preliminary considerations are addressed, material selection becomes the next critical step. Choosing appropriate wood and hardware significantly impacts the durability, stability, and aesthetic appeal of the table leaves.

Selecting Wood and Hardware

The choice of wood is influenced by several factors, including the existing table's wood species, the desired aesthetic, and the budget. Hardwoods like oak, maple, cherry, and walnut are popular choices for table construction due to their durability and attractive grain patterns. Softwoods, such as pine, are generally less suitable for high-use surfaces due to their susceptibility to dents and scratches.

Matching Wood Type: Ideally, the leaves should be constructed from the same wood species as the original table. This ensures consistency in color, grain, and hardness. If the original wood species is unavailable or prohibitively expensive, a closely matching alternative can be used. However, it is important to consider potential variations in color and grain, which may require staining or toning to achieve a uniform appearance.

Considering Wood Grain and Figure: The grain pattern and figure of the wood play a significant role in the overall aesthetic. Matching the grain orientation of the leaves to the tabletop is crucial for a seamless appearance. Techniques such as bookmatching, where two adjacent pieces of wood are flipped and joined to create a symmetrical grain pattern, can enhance the visual appeal. Selecting wood with similar figure, such as figuring caused by irregularities in grain growth like burl or curl, contributes to a cohesive aesthetic.

Selecting Appropriate Hardware: Hinges, latches, and other hardware components should be selected based on their durability, functionality, and aesthetic compatibility with the table. For drop-leaf tables, sturdy hinges are essential for supporting the weight of the leaves. Expanding table slides require latches or locking mechanisms to secure the leaves in place and prevent them from shifting during use. The finish of the hardware should complement the table's overall style and finish.

With proper planning and meticulous material selection, the construction phase can begin. This involves precisely measuring, cutting, joining, and shaping the wood to create leaves that seamlessly integrate with the existing table.

Constructing the Leaves

Accurate measurements are paramount throughout the construction process. Begin by carefully measuring the dimensions of the existing table and the required gap for the leaves. Double-check all measurements to minimize errors and ensure a precise fit. Using templates and jigs can improve accuracy and consistency when cutting multiple leaves.

Cutting and Shaping the Wood: Use a table saw or circular saw to cut the wood to the required dimensions. Ensure the cuts are straight and square. For curved edges or intricate shapes, use a jigsaw or band saw. Employ templates to guide the cutting process and ensure consistency. Sand the edges smooth after cutting to remove any rough spots or splinters.

Joining the Wood: Several methods can be used to join the individual pieces of wood together to form the leaves. Common techniques include using dowels, biscuits, or tongue-and-groove joints. Select a joining method that provides sufficient strength and stability for the intended use. Apply glue to the mating surfaces and clamp the pieces together until the glue dries completely. Ensure the surfaces are aligned properly during clamping to prevent warping or misalignment.

Integrating with the Extension Mechanism: This step is the most crucial and dependant on the mechanism in question. For expanding tables, ensuring that the thickness of the leaves matches the gap in the table when fully extended is critical. Any deviations will result in the leaves sitting above or below the table surface. Butterfly leaves require careful hinge placement for smooth operation. Drop-leaf tables need sturdy support systems. Ensure the leaves are robust enough to support significant weight. Testing the mechanism with the leaves inserted provides the chance to verify its functionality before proceeding to the finishing stage.

Shaping the edges of the leaves to match the existing tabletop is essential for a seamless transition. Use a router with an appropriate edge-forming bit to create the desired profile. Common edge profiles include rounded, beveled, and ogee. Sand the edges smooth after routing to remove any router marks and create a uniform surface. Pay attention to detail when shaping the edges to ensure they blend seamlessly with the existing table.

After completing the construction of the leaves, the finishing process begins. This involves sanding, staining, and applying a protective topcoat to enhance the wood's appearance and protect it from wear and tear. A well-executed finish can significantly improve the durability and aesthetic appeal of the table leaves.

Proper preparation is key to a successful finish. Sand the entire surface of the leaves with progressively finer grits of sandpaper to create a smooth, even surface. Start with a coarser grit (e.g., 120-grit) to remove any imperfections and then gradually move to finer grits (e.g., 180-grit, 220-grit) to refine the surface. Remove all sanding dust with a tack cloth before proceeding to the next step.

Applying stain enhances the wood's color and accentuates its grain pattern. Select a stain color that matches or complements the existing tabletop. Apply the stain evenly with a brush, cloth, or spray gun. Allow the stain to penetrate the wood for the recommended time and then wipe off any excess stain with a clean cloth. If a darker color is desired, apply additional coats of stain, allowing each coat to dry completely before applying the next.

A protective topcoat is essential for protecting the wood from scratches, stains, and moisture damage. Common topcoat options include varnish, lacquer, polyurethane, and oil-based finishes. Select a topcoat that is compatible with the stain used and provides the desired level of protection. Apply the topcoat in thin, even coats with a brush, spray gun, or cloth. Allow each coat to dry completely before applying the next. Lightly sand between coats with fine-grit sandpaper to remove any imperfections and create a smooth surface. Applying multiple coats of topcoat increases the durability and longevity of the finish.

Felt Leaves Diy For Table Gift Wrap And Garlands Made On 23rd

Diy Dining Table With Leaves Houseful Of Handmade

How To Make An Easy Faux Leaf Fall Table Runner Hearth And Vine

How To Make An Easy Faux Leaf Fall Table Runner Hearth And Vine

Diy Autumn Leaves Table Runner The Sweetest Occasion

Making Leaf Place Mats

Colorful Paper Leaf Garland For Fall Less Than Perfect Life Of Bliss

How To Make Dollar Tree Diy Table Runner With Burlap Leaves

24 Gorgeous Fall Leaf Crafts Easy Diy Decor A Piece Of Rainbow

Pretty Details Magnolia Leaves Table Runner Leaf Garland Centerpiece