Factory Reconditioned Ridgid Table Saws: A Comprehensive Overview

The world of woodworking often demands precision, power, and reliability. For many professionals and hobbyists alike, a table saw serves as the cornerstone of their workshop. Ridgid, a well-regarded brand in the power tool industry, offers a range of table saws known for their durability and performance. While new models provide the latest features and pristine condition, factory reconditioned Ridgid table saws present a cost-effective alternative, potentially delivering similar functionality at a reduced price. This article delves into the specifics of factory reconditioned Ridgid table saws, exploring their benefits, potential drawbacks, the refurbishment process, and factors to consider before making a purchase.

A factory reconditioned tool is one that has been returned to the manufacturer for various reasons, such as minor cosmetic defects, customer returns, or shipping damage. These tools are then thoroughly inspected, repaired, and tested by the manufacturer to meet specific operational standards. The resulting product is then offered for sale at a lower price than a new unit, providing an opportunity to acquire a high-quality tool while saving money.

Understanding the Refurbishment Process

The factory reconditioning process is crucial to ensuring the quality and reliability of these tools. It's more than just a quick cleaning and repackaging; it's a rigorous inspection and repair procedure. Here's a typical outline of what a Ridgid table saw might undergo during refurbishment:

Initial Inspection: The process begins with a comprehensive assessment of the returned table saw. Technicians meticulously examine the tool for any defects, damage, or missing parts. This includes evaluating the motor, blade, fence, miter gauge, and all safety mechanisms.

Diagnosis and Repair: Based on the initial inspection, technicians diagnose any problems and perform necessary repairs. This can range from replacing worn-out parts to fixing minor mechanical issues. Parts are often replaced with genuine Ridgid components to maintain the tool's original performance and longevity.

Cleaning and Refinishing: The table saw undergoes thorough cleaning to remove any dust, debris, or residue from previous use. Any cosmetic imperfections, such as scratches or dents, may be addressed to improve the tool's appearance. This may involve refinishing the table surface or repainting certain components.

Calibration and Adjustment: Proper calibration is essential for accurate cuts. Technicians carefully adjust the blade alignment, fence squareness, and miter gauge settings to ensure the table saw meets factory specifications. This step is critical for achieving precise and consistent results.

Testing and Certification: After repairs and adjustments, the table saw undergoes rigorous testing to verify its functionality and safety. This includes testing the motor's performance, the blade's cutting ability, and the proper operation of all safety features. The tool is then certified as meeting the manufacturer's quality standards.

Packaging and Resale: Once the table saw has passed all tests and inspections, it is carefully repackaged, often in a new or refurbished box. The packaging typically includes all original accessories, such as the blade, fence, miter gauge, and instruction manual. The reconditioned tool is then offered for sale at a discounted price, often with a limited warranty.

Benefits of Choosing a Factory Reconditioned Ridgid Table Saw

Purchasing a factory reconditioned Ridgid table saw offers several advantages, making it an appealing option for budget-conscious woodworkers:

Cost Savings: The most significant benefit is the reduced price compared to a new model. Factory reconditioned tools are typically offered at a substantial discount, allowing users to acquire a high-quality table saw without breaking the bank. The savings can be particularly attractive for those starting out in woodworking or those on a tight budget.

Quality Assurance: Factory reconditioned tools undergo a rigorous refurbishment process, ensuring they meet the manufacturer's quality standards. Unlike buying a used tool from a private seller, a factory reconditioned table saw has been thoroughly inspected, repaired, and tested by qualified technicians, providing greater confidence in its performance and reliability. The refurbishment process often includes replacing worn or damaged parts with genuine Ridgid components, further enhancing the tool's longevity.

Warranty Protection: Many factory reconditioned Ridgid table saws come with a limited warranty, providing additional peace of mind. The warranty typically covers defects in materials and workmanship, offering protection against unexpected repairs or malfunctions. While the warranty period may be shorter than that of a new tool, it still provides valuable coverage and demonstrates the manufacturer's confidence in the quality of the reconditioned product. It's crucial to carefully review the warranty terms and conditions before making a purchase.

Environmental Benefits: Choosing a factory reconditioned tool contributes to sustainable practices by reducing waste and conserving resources. By giving a second life to returned or slightly damaged tools, the reconditioning process minimizes the need for new manufacturing, lowering the environmental impact associated with the production and disposal of power tools.

Potential Drawbacks and Considerations

While factory reconditioned Ridgid table saws offer numerous benefits, it's essential to be aware of potential drawbacks and consider certain factors before making a purchase:

Cosmetic Imperfections: Factory reconditioned tools may exhibit minor cosmetic imperfections, such as scratches, dents, or blemishes. While these imperfections do not affect the tool's performance, some users may find them aesthetically unappealing. It's important to consider whether cosmetic appearance is a primary concern or if the focus is solely on functionality.

Limited Warranty: The warranty period for factory reconditioned tools is often shorter than that of new models. It's crucial to carefully review the warranty terms and conditions to understand the coverage and limitations. While the warranty provides protection against defects in materials and workmanship, it may not cover certain types of damage or wear and tear.

Availability: The availability of specific models of factory reconditioned Ridgid table saws may be limited. Reconditioned inventory depends on the number of returned tools and the demand for specific models. It may be necessary to check with multiple retailers or online marketplaces to find the desired model in reconditioned condition.

Potential for Underlying Issues: Although the refurbishment process aims to address any underlying issues, there is always a slight risk that a hidden problem may emerge after purchase. Thoroughly inspect the tool upon arrival and test its functionality to identify any potential issues early on. If any problems arise, contact the retailer or manufacturer's customer service department for assistance.

Researching the Seller: When purchasing a factory reconditioned Ridgid table saw, it is paramount to purchase from authorized retailers or directly from Ridgid. This ensures that the tool has undergone the proper refurbishment process and is backed by a warranty. Purchasing from unauthorized sellers can lead to acquiring a poorly refurbished tool or a counterfeit product.

The following are key features to consider that can help guide purchase decisions regarding factory reconditioned Ridgid table saws.

Key Features to Consider Before Purchasing

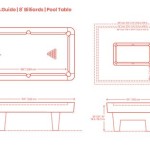

Before committing to a factory reconditioned Ridgid table saw, prospective buyers should carefully evaluate their needs and compare specifications of various models. Factors such as the type of projects, the volume of work, and the available workspace will influence the choice. Some key features to consider include:

Motor Power: The table saw's motor power determines its ability to cut through different types of wood. Higher horsepower motors are better suited for cutting thicker hardwoods or performing demanding tasks. For occasional hobbyists working with softer woods, a lower horsepower motor may suffice. Assess the type of projects that will be undertaken most frequently to determine the appropriate motor power.

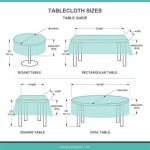

Blade Size and Type: The size of the blade determines the maximum cutting depth. Table saws typically use 10-inch or 12-inch blades. The type of blade also affects the quality of the cut. Different blade types are designed for specific materials and applications, such as ripping, crosscutting, or dadoing. Consider the range of materials that will be cut and select a blade that is appropriate for those materials.

Fence System: The fence system is crucial for accurate and consistent cuts. A high-quality fence should be easy to adjust, lock securely in place, and remain parallel to the blade. Look for a fence system that provides precise adjustments and minimal deflection. A fence with micro-adjustment capabilities can further enhance accuracy.

Miter Gauge: The miter gauge is used for making angled cuts. A miter gauge should be accurate, easy to adjust, and provide a smooth range of motion. Look for a miter gauge with positive stops at common angles, such as 45 degrees and 90 degrees. An adjustable miter gauge can be particularly useful for complex projects requiring precise angles.

Safety Features: Table saws can be dangerous if not used properly. Safety features such as blade guards, anti-kickback pawls, and push sticks are essential for preventing accidents. Ensure that the table saw has all necessary safety features and that they are in good working order. Always follow safety guidelines and wear appropriate safety gear when operating a table saw.

Dust Collection: Woodworking can generate a significant amount of dust, which can be harmful to health. A table saw with an effective dust collection system can help minimize dust exposure and keep the workspace clean. Look for a table saw with a dust port that can be connected to a shop vacuum or dust collector. Consider the efficiency of the dust collection system and its ability to capture dust from both above and below the table.

Table Size and Extension Wings: The size of the table determines the amount of support available for larger workpieces. Table saws with extension wings provide additional support for cutting larger sheets of plywood or other materials. Consider the size of the projects that will be undertaken most frequently and choose a table saw with an appropriately sized table and extension wings.

Portability: If the table saw will need to be moved frequently, consider a portable model with features such as folding legs and wheels. Portable table saws are typically smaller and lighter than stationary models, making them easier to transport and store. However, portable table saws may have less power and smaller table sizes than stationary models.

A factory reconditioned Ridgid table saw can be a smart investment for woodworkers seeking a balance of quality, performance, and affordability. By carefully considering the refurbishment process, potential drawbacks, and essential features, prospective buyers can make an informed decision and choose a table saw that meets their specific needs and budget.

Ridgid 15 Amp 10 In Compact Table Saw Direct Tools Site

Ridgid 10 Table Saw Direct Tools Site

Factory Reconditioned Ridgid Zrr4513 15 Amp 10 In Portable Table Saw With Mobile Stand Best Jobsite

Ridgid 15 Amp 10 In Compact Table Saw Direct Tools Site

Ridgid 15 Amp 10 In Compact Table Saw Direct Tools Site

Ridgid 15 Amp 10 In Compact Table Saw Direct Tools Site

Ridgid 15 Amp 10 In Compact Table Saw Direct Tools Site

Ridgid 15 Amp 10 In Compact Table Saw With Folding Stand Direct Tools Site

Ridgid 15 Amp 10 In Compact Table Saw Direct Tools Site

Ridgid 18 Volt Compact Band Saw Tool Only Factory Reconditioned Com