Outdoor Table Bases for Granite Tops: A Comprehensive Guide

Selecting the appropriate table base for a granite top in an outdoor setting requires careful consideration of several factors. Granite, a dense and durable natural stone, presents unique weight and stability challenges compared to lighter tabletop materials. Therefore, the table base must be robust enough to support the granite’s weight and withstand environmental elements, ensuring both safety and longevity. This article explores various aspects of choosing the right outdoor table base for granite tops, covering material selection, design considerations, installation practices, and essential maintenance.

Understanding the Importance of a Sturdy Table Base

The primary function of a table base is to provide stable and secure support for the tabletop. When the tabletop material is granite, this requirement becomes significantly more critical. Granite is a heavy material, typically weighing between 12 to 18 pounds per square foot, depending on the thickness and type of granite. Consequently, a weak or poorly designed table base can lead to several problems. Firstly, it can become unstable, potentially causing the table to wobble or even tip over, especially in windy conditions. Secondly, it can strain under the weight of the granite, leading to structural failure over time. This can result in damage to both the table base and the granite top itself. Thirdly, an inadequate base can pose a safety hazard to anyone using the table, potentially leading to injuries if the table collapses.

Therefore, selecting a table base made from durable materials and designed with sufficient load-bearing capacity is crucial. The base should be engineered to distribute the weight of the granite evenly across its surface, minimizing stress points and ensuring long-term stability. It is also important to consider the base's footprint. A wider base provides greater stability and reduces the risk of tipping, especially for larger granite tops.

Key Materials for Outdoor Granite Table Bases

The choice of material for an outdoor granite table base is paramount, as it directly impacts the base's durability, resistance to weathering, and overall aesthetic appeal. Several materials are commonly used, each with its own set of advantages and disadvantages.

Cast Iron: Cast iron is a traditional and popular choice for outdoor table bases due to its inherent strength and weight. It offers exceptional stability and can readily support the heavy weight of granite tops. Cast iron bases are typically treated with a protective coating, such as powder coating or epoxy, to prevent rust and corrosion. However, cast iron can be susceptible to rust if the protective coating is damaged or worn away. Regular maintenance, including cleaning and re-coating, is therefore necessary to prolong the life of a cast iron base.

Stainless Steel: Stainless steel is another excellent option for outdoor granite table bases. Its primary advantage is its superior resistance to corrosion, making it ideal for environments with high humidity or exposure to saltwater. Stainless steel is also a very strong and durable material, capable of supporting heavy loads without bending or flexing. Furthermore, stainless steel offers a modern and sleek aesthetic that complements various outdoor décor styles. However, stainless steel bases can be more expensive than cast iron bases.

Aluminum: Aluminum is a lightweight yet strong material that is also highly resistant to corrosion. Aluminum bases are easier to move than cast iron or stainless steel bases, which can be an advantage for tables that need to be frequently repositioned. While aluminum is not as inherently strong as steel, it can be alloyed with other metals to increase its strength and load-bearing capacity. Aluminum bases are often powder-coated to provide additional protection and enhance their appearance.

Wrought Iron: Wrought iron offers a classic and elegant aesthetic that can add a touch of sophistication to any outdoor space. Wrought iron is a strong and durable material, although it is more susceptible to rust than stainless steel or aluminum. Regular maintenance, including cleaning and painting, is required to prevent corrosion and keep the base looking its best. Wrought iron bases are often intricately designed, adding to their visual appeal.

Concrete: Concrete table bases are becoming increasingly popular for their modern and minimalist aesthetic. Concrete is a very strong and durable material, capable of supporting heavy granite tops. Concrete bases are also relatively low-maintenance, requiring minimal upkeep. However, concrete bases can be very heavy and difficult to move. They are also susceptible to cracking in extreme temperatures if not properly sealed.

Design Considerations and Installation Practices

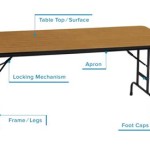

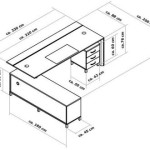

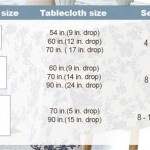

Beyond material selection, several design considerations and installation practices are essential to ensure the stability and longevity of an outdoor granite table. The design of the base should complement the shape and size of the granite top. For example, a round granite top may require a central pedestal base, while a rectangular or square top may be better supported by a four-legged base. The size of the base should be proportional to the size of the granite top, providing adequate support without being visually overwhelming.

The height of the table base should also be carefully considered. Standard dining table heights are typically around 30 inches, while coffee table heights are around 18 inches. The base height should be chosen to achieve the desired overall table height, taking into account the thickness of the granite top.

Proper installation is crucial for ensuring the stability and safety of the table. The granite top should be securely attached to the base using appropriate fasteners. The type of fastener will depend on the material of the base and the thickness of the granite. Common fastening methods include screws, bolts, and epoxy adhesives. It is essential to use fasteners that are specifically designed for outdoor use to prevent corrosion.

In some cases, it may be necessary to use a metal plate or frame between the granite top and the table base to provide additional support and distribute the weight more evenly. This is particularly important for larger or heavier granite tops. The metal plate or frame should be made from a durable material, such as steel or aluminum, and should be securely attached to both the granite top and the table base.

For uneven surfaces, adjustable feet can be added to the table base to level the table and prevent wobbling. Adjustable feet are particularly useful for outdoor settings where the ground may not be perfectly level. The feet should be made from a durable material that is resistant to corrosion, such as stainless steel or plastic.

Finally, it is important to consider the overall aesthetic of the table. The table base should complement the style of the granite top and the surrounding outdoor décor. The base can be painted or powder-coated in a variety of colors to match or contrast with the granite. Decorative elements can also be added to the base to enhance its visual appeal.

Maintenance and Care for Outdoor Granite Table Bases

Proper maintenance is essential for prolonging the life of an outdoor granite table base and ensuring its continued stability and safety. The specific maintenance requirements will vary depending on the material of the base. However, some general guidelines apply to all types of bases.

Regular cleaning is important to remove dirt, debris, and stains. The base should be cleaned with a mild soap and water solution and a soft cloth or brush. Avoid using harsh chemicals or abrasive cleaners, as these can damage the finish of the base. For stubborn stains, a specialized cleaning product may be necessary. Always follow the manufacturer's instructions when using any cleaning product.

For metal bases, regular inspection for rust or corrosion is essential. If rust is detected, it should be removed immediately using a wire brush or sandpaper. The affected area should then be cleaned and primed before being painted or coated with a protective finish. For cast iron bases, it may be necessary to re-coat the entire base periodically to prevent rust. For stainless steel bases, a stainless steel cleaner can be used to remove fingerprints and water spots.

For wooden bases, regular sealing or staining is necessary to protect the wood from moisture and UV damage. The frequency of sealing or staining will depend on the type of wood and the climate. Inspect the wood regularly for signs of rot or decay. If rot is detected, the affected area should be removed and replaced with new wood.

For all types of bases, it is important to tighten any loose screws or bolts regularly. Loose fasteners can compromise the stability of the table and lead to damage over time. The fasteners should be tightened using the appropriate tools. If the fasteners are corroded or damaged, they should be replaced.

During the off-season, it is recommended to store the table indoors or cover it with a protective cover. This will help to protect the base from the elements and prolong its life. If the table is stored outdoors, be sure to elevate it off the ground to prevent moisture damage.

By following these maintenance guidelines, it is possible to keep an outdoor granite table base in good condition for many years, ensuring its continued stability, safety, and aesthetic appeal.

Granite Dining Tables Table Outdoor Tops Patio Makeover

Modern Dining Table Granite Top With Steel Square Legs Denmark

Modern Dining Table Granite Top With Steel Square Legs Denmark

Modern Dining Table Granite Top With Steel Square Legs Marble

Outdoor Dining Table Setting Granite Speckled 2 1 Em20055 Base 6 O Courtyard Living

Granite Indoor Outdoor Restaurant Table Tops Uba Tuba Oakstreetmfg

Cast Iron Table With A Granite Top For At 1stdibs Wrought Base

Granite Top Outdoor Table With Cedar Farmhouse Base Country Living Room Houston By Sovereign Carpentry Houzz Ie

Garden Furniture ǀ Stone And Iron Table Atelier Alain Bidal

Granite Indoor Outdoor Restaurant Table Tops Golden Peach Oakstreetmfg