Using Galvanized Pipe for Table Legs: A Comprehensive Guide

Galvanized pipe has emerged as a popular material for crafting table legs, offering a unique blend of industrial aesthetic, durability, and affordability. Its rugged appearance complements a wide range of tabletop materials, from reclaimed wood to sleek concrete, making it a versatile choice for both DIY enthusiasts and professional furniture makers. This article details the advantages, considerations, and steps involved in using galvanized pipe for table legs, providing a complete guide for anyone interested in this construction method.

Galvanization is a process that involves coating steel or iron with a layer of zinc to protect it from corrosion. This zinc coating acts as a barrier, preventing corrosive substances from reaching the underlying metal. The result is a material highly resistant to rust and wear, making it suitable for both indoor and outdoor applications. In the context of table legs, this means a reduced risk of corrosion from moisture, spills, or general environmental exposure, thus extending the lifespan of the furniture piece.

The choice of galvanized pipe for table legs is driven by multiple factors, including aesthetic appeal, structural strength, and cost-effectiveness. Understanding these factors can help individuals make informed decisions about whether this material aligns with their specific project requirements and design preferences.

The Appeal of Industrial Aesthetic

One of the primary reasons individuals opt for galvanized pipe table legs is their inherent industrial look. This aesthetic embodies a sense of raw functionality and utilitarian design, often associated with factories, warehouses, and urban environments. The exposed pipe threads, the metallic sheen of the galvanized coating, and the robust construction all contribute to this distinct visual appeal. This style complements various design schemes, including minimalist, modern, rustic, and steampunk.

The industrial aesthetic offers a stark contrast to more traditional table leg options, such as turned wood or polished metal. This contrast can be particularly effective when paired with natural or reclaimed materials, such as a rough-hewn wooden tabletop. The juxtaposition of the raw, industrial legs with the organic texture of the wood creates a visually interesting and balanced piece of furniture. This style is not limited to specific room designs either. Galvanized pipe legs can integrate nicely into kitchens, dining rooms, living rooms, or even outdoor patio spaces.

Customization also plays a role in the aesthetic appeal. While the standard galvanized finish provides a distinct look, the pipes can be painted or treated to achieve different visual effects. For example, painting the pipes black or a metallic color can enhance their industrial character, while applying a clear coat can protect the finish and prevent tarnishing.

Structural Integrity and Durability

Beyond aesthetics, galvanized pipe offers significant structural advantages for table legs. Steel, the base material for galvanized pipe, possesses high tensile strength and rigidity. This inherent strength allows the table legs to withstand significant weight and stress without bending or buckling. This is particularly important for larger tables or those intended to support heavy items. The galvanization process further improves the durability by providing a protective coating against corrosion, ensuring that the structural integrity of the legs is maintained over time.

The threaded connections used to assemble the pipe legs create a strong and secure joint. When properly tightened, these connections provide a rigid framework that contributes to the overall stability of the table. The use of flanges or floor flanges to attach the legs to the tabletop further enhances stability by distributing the weight evenly across a larger surface area.

Compared to other common materials used for table legs, such as wood or plastic, galvanized pipe offers superior resistance to impact, scratches, and other forms of physical damage. This makes it a suitable choice for environments where the table may be subjected to heavy use or potential abuse. The material's robustness also makes it suitable for outdoor applications, where it can withstand exposure to the elements, including rain, sun, and temperature fluctuations.

Cost-Effectiveness and Accessibility

Compared to custom-fabricated metal legs or high-end wood options, galvanized pipe can be a cost-effective solution for table legs. The price of galvanized pipe is typically lower than that of other metals such as stainless steel or aluminum, and it is readily available at most hardware stores and home improvement centers. The ease of sourcing the materials contributes to the overall affordability of the project.

The relative simplicity of working with galvanized pipe compared to materials that require specialized tools and techniques also contributes to cost savings. While cutting and threading pipe can be done with specialized equipment, many hardware stores offer pipe cutting and threading services at a minimal cost. This eliminates the need for individuals to invest in expensive tools and equipment, making the project more accessible to a wider range of skill levels.

The modular nature of galvanized pipe also allows for flexibility in design and construction. Individual sections of pipe can be easily connected and reconfigured, allowing for adjustments in height, width, and overall table dimensions. This adaptability can be particularly useful for DIY projects or for creating custom furniture pieces that meet specific requirements. Furthermore, the availability of various fittings, such as elbows, tees, and couplings, allows for creating intricate and unique leg designs without requiring welding or other specialized fabrication techniques.

Considerations for Working with Galvanized Pipe

While galvanized pipe offers numerous advantages for table legs, there are also several considerations to keep in mind. These include selecting the appropriate pipe size and fittings, ensuring proper preparation and assembly, and addressing potential safety concerns.

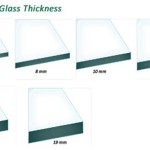

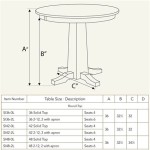

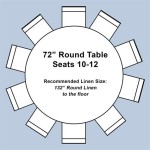

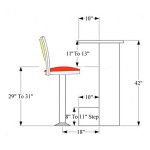

First, the diameter of the pipe needs to be chosen based on the size and weight of the tabletop. Thicker pipes offer greater strength and stability, but they also increase the overall weight and cost of the project. It is essential to strike a balance between structural integrity and aesthetic proportions. For smaller tables or those intended to support lighter loads, a smaller diameter pipe may be sufficient. For larger tables or those intended to support heavy items, a larger diameter pipe is recommended.

The selection of appropriate fittings is also crucial for ensuring a stable and visually appealing design. Floor flanges are commonly used to attach the legs to the tabletop, providing a secure and stable connection. Elbows, tees, and couplings can be used to create various leg designs and to connect multiple sections of pipe. It is important to choose fittings that are compatible with the pipe size and threading, and to ensure that all connections are properly tightened to prevent loosening or wobbling.

Proper preparation and assembly are essential for achieving a professional and durable result. Before assembly, the pipes should be cleaned to remove any dirt, grease, or debris. Pipe threads should be inspected for damage and, if necessary, cleaned and lubricated to ensure a smooth and secure connection. When tightening the fittings, it is important to use appropriate tools, such as pipe wrenches, to avoid damaging the pipe or fittings. Over-tightening can strip the threads, while under-tightening can result in loose connections. Applying pipe thread sealant to the threads can help to ensure a watertight and airtight seal, further preventing corrosion and loosening.

Finally, potential safety concerns should be addressed when working with galvanized pipe. Galvanized coatings can release toxic fumes when heated, so it is essential to avoid welding or cutting galvanized pipe in poorly ventilated areas. Wearing appropriate protective gear, such as gloves and eye protection, is also recommended when handling galvanized pipe to prevent cuts, scrapes, and eye irritation. While galvanized pipe is generally safe for use in furniture applications, individuals with sensitivities to zinc may experience skin irritation from prolonged contact. In such cases, wearing gloves or applying a protective coating to the pipe can help to minimize exposure.

Ultimately, using galvanized pipe for table legs is a worthwhile endeavor for those seeking a durable, aesthetically pleasing, and cost-effective solution. By understanding the material's properties, advantages, and limitations, individuals can create stable, functional, and visually compelling furniture pieces that reflect their personal style and design sensibilities.

Iron Pipe Table Legs Metal For Coffee Industrial Kit

Make Your Own Stylish Metal Pipe Coffee Table

Carly Reclaimed Scaffolding Board Dining Table Meeting With Galvanized Pipe Legs Bespoke Furniture By Www Urbangrain Co Singapore

Diy Plumbing Pipe Table Tutorial

51 Diy Pipe Table Ideas And Inspiration Simplified Building

Blog Simply Janelle Designs Galvanized Pipe Furniture Industrial Kitchen Shelves Table Metal

Build A Diy Pipe Dream Of Table Beach Metro Community News

51 Diy Pipe Table Ideas And Inspiration Simplified Building

Industrial Wood Desk Kitchen Dining Table With Black Galvanized Steel Pipe Legs Built By Hand Furniture

Project Galvanised Pipe Desk Bunnings Work Community