Garment Cutting Table Size: A Comprehensive Guide

The garment cutting table is an indispensable piece of equipment in the apparel manufacturing industry, playing a crucial role in transforming fabric into precisely cut pieces ready for sewing. Its size is a critical factor that directly impacts efficiency, productivity, and the overall quality of the final product. Selecting the appropriate cutting table size is therefore an important decision for garment manufacturers, designers, and even hobbyist sewers. This article will delve into the various aspects of garment cutting table sizes, examining the factors that influence the choice, the standard dimensions available, and the implications of selecting an unsuitable size.

The primary function of a garment cutting table is to provide a stable and spacious surface for laying out fabric, marking patterns, and cutting the material according to the design specifications. A well-chosen cutting table facilitates accuracy and reduces the risk of errors, leading to higher quality garments and minimizing fabric waste. The size of the table directly affects the number of layers of fabric that can be cut simultaneously, impacting throughput and overall production speed. Inadequate table size can hinder efficiency, leading to bottlenecks and increased labor costs.

Factors Influencing Garment Cutting Table Size Selection

Several factors should be considered when determining the optimal size of a garment cutting table. These include the type of garments being produced, the production volume, the available workspace, and the cutting methods employed.

Garment Type and Pattern Size: The type of garments manufactured significantly influences the required table size. For example, producing large items such as coats, dresses, or trousers necessitates a larger cutting surface compared to smaller items like shirts or children's clothing. The size and complexity of the patterns also play a vital role. Garments with large, intricate patterns require a larger table to accommodate the complete pattern layout and ensure accurate cutting. The larger the pattern pieces, the greater the need for ample workspace on the cutting table.

Production Volume: The volume of garments produced dictates the need for a larger or smaller table. High-volume production necessitates a table that can accommodate multiple layers of fabric, allowing for simultaneous cutting of many garment pieces. This requires a larger surface area to spread the fabric efficiently and minimize the number of cutting operations. Low-volume production, on the other hand, may only require a smaller table as fewer layers of fabric are typically cut at a time.

Available Workspace: The physical limitations of the available workspace are a crucial consideration. The cutting table must fit comfortably within the designated area without obstructing movement or creating safety hazards. Prior to purchasing a cutting table, accurate measurements of the workspace should be taken to ensure that the selected table dimensions are appropriate. In settings with limited space, foldable or modular cutting tables can offer a practical solution.

Cutting Methods: The cutting method employed, whether manual or automated, also influences the optimal table size. Manual cutting typically requires more space for maneuvering scissors or rotary cutters. Automated cutting systems, such as those utilizing computerized cutting machines, often require specific table sizes to accommodate the equipment. The use of automated systems often necessitates a larger cutting surface area to maximize efficiency and throughput.

Fabric Width: The width of the fabric rolls used in production is another critical factor. The cutting table's width must be sufficient to accommodate the widest fabric rolls used. This ensures that the fabric can be laid out without overlapping the edges of the table, which can lead to inaccuracies in cutting and material waste. Fabric width standards can vary by region and application, which needs assessment during the selection process.

Standard Garment Cutting Table Dimensions

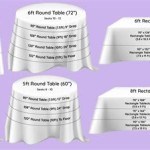

Garment cutting tables are available in a range of standard sizes to accommodate various needs and production volumes. These dimensions typically refer to the length and width of the table surface. While custom sizes can be made, standard dimensions enable manufacturers to leverage readily available materials and construction techniques.

Small Cutting Tables: These tables typically range from 4 feet to 6 feet in length and 3 feet to 4 feet in width. They are suitable for small-scale operations, hobbyist sewers, and designers working on sample garments or prototypes with limited space. These smaller tables are often foldable or modular, making them easy to store when not in use.

Medium Cutting Tables: Medium-sized cutting tables generally range from 6 feet to 8 feet in length and 4 feet to 5 feet in width. These tables are ideal for small to medium-sized garment manufacturing businesses, tailor shops, and educational institutions. They provide sufficient space for cutting multiple layers of fabric and accommodate a wider range of garment sizes and styles.

Large Cutting Tables: Large cutting tables typically range from 8 feet to 12 feet or more in length and 5 feet to 6 feet or more in width. These tables are designed for high-volume garment production and are commonly found in large-scale manufacturing facilities. They can accommodate numerous layers of fabric, allowing for efficient cutting of multiple garment pieces simultaneously. These large tables are able to accommodate large garment pieces. Their expanded dimensions reduce the need to move fabric during cutting, which enhances accuracy.

Custom Cutting Tables: Custom cutting tables can be fabricated to meet specific requirements. These tables can be designed to accommodate unique workspace constraints or specialized cutting needs. They are often used in industries that require the production of unusually sized or shaped garments, such as for theatrical costumes or industrial textiles.

Implications of Incorrect Cutting Table Size

Choosing the wrong cutting table size can have significant consequences for garment manufacturers. An undersized table can lead to inefficiencies, inaccuracies, and increased material waste, while an oversized table can occupy valuable workspace and increase costs unnecessarily.

Inefficiency and Reduced Productivity: An undersized cutting table can significantly hinder efficiency and reduce productivity. Limited workspace requires frequent repositioning of fabric and patterns, slowing down the cutting process. This can create bottlenecks in the production line and ultimately increase lead times. Cutting smaller batches of fabric also requires more frequent setups, further reducing overall productivity. Inefficiencies increase operating costs.

Inaccuracies and Quality Issues: Insufficient cutting table space can lead to inaccuracies in cutting, resulting in garments that do not meet the required specifications. Overlapping or improperly aligned fabric layers can cause variations in size and shape, affecting the overall quality of the final product. Inaccurate cutting leads to increased rework, rejects, and higher production costs.

Increased Material Waste: A too-small cutting table may force manufacturers to cut fabric inefficiently, leading to increased material waste. When fabric must be repositioned frequently, there is a higher risk of errors and miscuts, resulting in unusable fabric scraps. Minimizing fabric waste is crucial for reducing costs and promoting sustainable manufacturing practices.

Safety Concerns: An inappropriately sized cutting table can create safety hazards. An undersized table can force operators to work in awkward positions, increasing the risk of strain and injury. An oversized table can obstruct walkways and create trip hazards. A well-chosen cutting table promotes a safe and ergonomic working environment.

Increased Costs: Choosing the right cutting table size is an investment that can pay off in the long run. An undersized table can lead to hidden costs associated with inefficiencies, rework, and material waste. An oversized table may require additional floor space and higher initial investment costs. A properly sized cutting table optimizes efficiency, reduces costs, and contributes to the overall profitability of the business.

Selecting the right garment cutting table size is thus a critical decision that requires careful consideration of various factors, including the type of garments produced, the production volume, the available workspace, and the cutting methods employed. By carefully assessing these factors and choosing the appropriate table size, garment manufacturers and designers can optimize their production processes, improve efficiency, and ensure the quality of their final products. When a cutting table is correctly sized, fabric waste is minimized, worker efficiency is maximized, and the workspace is optimized. This leads to higher quality garments and increased profitability.

Fabric Cutting Table Size 2400 X 1800 900 Mm At Rs 15000 In New Delhi Id 13795325773

Free Standing Sheet With Frame Material Cutting Table For Garments Size 8 Lx 3 Wx3 H At Rs 10000 In Coimbatore

Fabric Cutting Tables

Garment Cutting Table Size 9 X 6 Feet At Rs 11000 In Tiruppur Id 9904946091

Cutting Table Length And Width

Fabric Cutting Tables

Buy Fabric Cutting Table Grid Top Silver Legs

Cutting Table 48 X 60 Ct001

Fabric Cutting Table Thickness 12 To 15mm At Rs 5800 In Ludhiana Id 21625219691

Fabric Cutting Table Size 2400 X 1800 900 Mm At Rs 15000 In New Delhi Id 13795325773

Related Posts