DIY Extendable Dining Table: A Comprehensive Guide

The need for adaptability in modern living spaces has driven the popularity of multi-functional furniture. The extendable dining table exemplifies this trend, offering a compact solution for everyday use that can be readily expanded to accommodate guests. Building an extendable dining table as a DIY project provides a unique opportunity to customize dimensions, materials, and aesthetics to perfectly suit individual needs and preferences. This article provides a detailed guide to designing and constructing an extendable dining table, covering key considerations, essential steps, and potential challenges.

Before embarking on the construction process, a thorough understanding of extendable table mechanics is crucial. Extendable tables typically employ one of several mechanisms to expand their surface area. These mechanisms directly influence the design and complexity of the project.

Drop-leaf mechanisms are relatively simple, involving hinged leaves that fold down when not in use and are supported by brackets or legs when raised. Butterfly leaf mechanisms conceal the leaf within the table itself, rotating into place to extend the table. More complex variations involve multiple leaves that slide out from beneath the main tabletop or are stored separately and inserted into the table when needed. The choice of mechanism will dictate the table's overall structure and the degree of precision required during construction.

Planning and Design Considerations

The initial phase of any DIY project involves meticulous planning and design. Several critical considerations will shape the final product, including the desired dimensions, the chosen extension mechanism, the material selection, and the overall aesthetic.

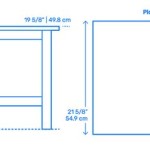

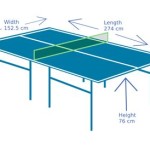

Determining the appropriate dimensions for the table is paramount. This involves considering the typical number of diners and the maximum number of guests the table should accommodate when extended. The room's dimensions must also be taken into account to ensure the table fits comfortably in both its compact and extended configurations. Standard dining table heights range from 29 to 31 inches, but this can be adjusted to suit individual preferences.

The selection of the appropriate extension mechanism is a crucial decision. As previously mentioned, various mechanisms exist, each with its own advantages and disadvantages. Drop-leaf mechanisms are relatively straightforward to implement but may not provide the same level of stability as more complex systems. Butterfly leaf mechanisms offer convenience by storing the leaf within the table but require more intricate joinery. Slide-out or insertable leaves offer maximum flexibility in terms of extension size but necessitate careful storage solutions for the leaves when not in use.

Material selection is another critical aspect of the design process. Hardwoods such as oak, maple, and cherry are popular choices for dining tables due to their durability and aesthetic appeal. Softwoods like pine are more affordable but may be more susceptible to dents and scratches. Plywood or MDF can be used for the table's core structure, providing stability and a smooth surface for veneer or other finishes. The choice of material will also influence the type of joinery required. Hardwoods typically require stronger joinery techniques than softwoods or manufactured wood products.

The overall aesthetic of the table should complement the existing décor of the dining room. This involves considering the shape of the tabletop, the style of the legs, and the chosen finish. Rectangular tabletops are the most common, but oval or round tabletops can also be used. Table legs can range from simple straight legs to more ornate turned legs. The finish can be a natural oil finish, a stain and varnish combination, or a painted finish, depending on the desired look.

Detailed drawings and cut lists are essential for successful construction. These drawings should include all dimensions, joinery details, and hardware specifications. A cut list specifies the exact size and quantity of each piece of lumber required for the project. Accurate drawings and cut lists will minimize errors and ensure that the table is constructed to the desired specifications.

Construction Process: A Step-by-Step Guide

The construction of an extendable dining table involves several key steps, starting with preparing the lumber and culminating in the final finishing touches. Accurate measurements, precise cuts, and proper joinery are essential for a structurally sound and aesthetically pleasing result.

The first step is to prepare the lumber according to the cut list. This involves cutting the lumber to the specified dimensions using a saw. It is crucial to ensure that all cuts are square and accurate. The lumber should then be planed to the desired thickness and sanded smooth. This will create a clean and uniform surface for joinery and finishing.

The next step is to assemble the table frame. The frame provides the structural support for the tabletop and legs. The frame is typically constructed using mortise and tenon joints, dowel joints, or pocket hole screws. Mortise and tenon joints are the strongest but require more skill and precision to execute. Dowel joints are easier to create but may not be as strong. Pocket hole screws are the simplest option but may not be as aesthetically pleasing. Regardless of the chosen joinery method, it is crucial to ensure that all joints are tight and secure.

Once the frame is assembled, the legs can be attached. The legs can be attached using screws, bolts, or mortise and tenon joints. The method of attachment will depend on the style of the legs and the overall design of the table. It is essential to ensure that the legs are securely attached and that the table is stable.

The next step is to construct the tabletop. The tabletop can be made from solid wood, plywood, or MDF. If using solid wood, the boards should be joined together using glue and clamps. It is crucial to ensure that the boards are aligned properly and that the glue is evenly distributed. If using plywood or MDF, the edges should be sealed to prevent moisture absorption.

The chosen extension mechanism is then implemented. This involves installing the hinges, slides, or other hardware required for the particular mechanism chosen. This step requires careful attention to detail and adherence to the manufacturer's instructions.

The final step is to finish the table. This involves sanding the entire table smooth and applying the desired finish. The finish can be a natural oil finish, a stain and varnish combination, or a painted finish. It is essential to apply the finish evenly and to allow it to dry completely before using the table.

Addressing Potential Challenges

Building an extendable dining table as a DIY project can present several challenges. Addressing these challenges proactively can minimize frustration and ensure a successful outcome.

One common challenge is achieving accurate cuts and precise joinery. Inaccurate cuts can result in gaps or misalignments, compromising the table's structural integrity and aesthetic appeal. Investing in quality measuring tools and practicing cutting techniques is essential. Utilizing jigs and templates can also improve accuracy. When creating joinery, careful marking and precise execution are crucial. Dry-fitting the components before applying glue can help identify and correct any errors.

Another challenge is ensuring the stability of the extended table. Extendable tables are inherently more complex structures than fixed tables, and the extension mechanism can introduce potential weak points. Proper design and construction techniques are crucial to mitigate this risk. The frame should be robust and well-supported. The extension mechanism should be strong and reliable. Additional support legs or brackets may be necessary for larger extensions.

Achieving a smooth and even finish can also be challenging. Uneven sanding, improper application of finish, or dust contamination can result in a less-than-desirable appearance. Thoroughly sanding the table before applying the finish is essential. Using high-quality finish and applying it in thin, even coats is recommended. Working in a dust-free environment and allowing the finish to dry completely between coats will minimize imperfections.

Finally, selecting the appropriate extension mechanism can be a challenge. The choice of mechanism depends on several factors, including the desired extension size, the available space, and the skill level of the builder. Researching different mechanisms and carefully considering their advantages and disadvantages is crucial. Consulting with experienced woodworkers or reviewing online resources can provide valuable insights. It may be beneficial to practice implementing the chosen mechanism on a smaller-scale project before incorporating it into the final table.

By addressing these potential challenges proactively, individuals can successfully construct a beautiful and functional extendable dining table that meets their specific needs and preferences. The DIY approach allows for complete customization and the satisfaction of creating a lasting piece of furniture.

Diy Farmhouse Table With Extension Leaves Plans Sweet Tooth Life

Build An Expandable Dining Table That Can Seat Ten And Fit In A Closet Chairs Diy

How To Make An Extendable Dining Table Transformer Diy Polkilo

Making A Table Expand Finewoodworking

How To Make An Extendable Dining Table With Solid Maple Tiny Apartment Build Ep 8

Diy Farmhouse Table With Extensions Addicted 2

Diy Farmhouse Table With Extension Leaves Plans Sweet Tooth Life

Making A Table Expand Finewoodworking

Expandable Formal Dining Table That Seats Ten And Fits In A Closet 22 Steps With S Instructables

An Uncommon Storage Space The Dining Table Expandable Diy