Garden Table Woodworking Plans: A Comprehensive Guide

Constructing a garden table independently can be a rewarding experience, allowing for a customized outdoor furnishing perfectly suited to specific needs and aesthetic preferences. Utilizing available woodworking plans provides a structured approach to this project, ensuring a successful outcome. This article will examine the crucial aspects of garden table woodworking plans, including choosing the right design, selecting appropriate materials, understanding essential tools and techniques, and addressing common challenges.

Choosing the Right Garden Table Design

The initial step in any woodworking project is selecting a design that aligns with individual skill levels, available space, and desired functionality. Garden table woodworking plans are diverse, ranging from simple, rustic picnic tables to more elaborate, multi-tiered designs suitable for dining and entertaining. Several factors should be considered during the selection process.

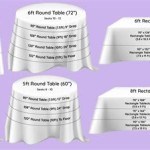

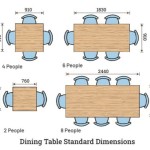

Firstly, the intended use of the table is paramount. A small, bistro-style table might suffice for a compact balcony or patio, while a larger rectangular table would be more appropriate for accommodating larger gatherings. Consider the number of people who will typically use the table and choose a design that provides adequate seating and surface area.

Secondly, the available space must be accurately measured. It is crucial to account for not only the footprint of the table itself but also the surrounding area required for comfortable movement and seating. Overcrowding can diminish the enjoyment of the outdoor space.

Thirdly, the aesthetic style should complement the existing outdoor décor. Garden tables are available in a wide range of styles, from traditional to contemporary. Consider the material choices and finishes that will best integrate with the overall design of the garden or patio.

Fourthly, skill level plays a significant role. Novice woodworkers should opt for simpler designs that minimize intricate cuts and complex joinery. More experienced woodworkers can tackle more challenging projects with intricate detailing and advanced construction techniques. Selecting a plan that matches the available skillset will increase the likelihood of a successful and enjoyable build.

Finally, accessibility to clear and comprehensive plans is critical. Look for plans that include detailed diagrams, precise measurements, and step-by-step instructions. Online reviews and testimonials can provide valuable insights into the clarity and accuracy of different plans.

Selecting Appropriate Materials for Garden Tables

The choice of materials significantly impacts the durability, aesthetic appeal, and maintenance requirements of a garden table. Wood is a popular choice due to its natural beauty and workability, but other materials such as metal and composite lumber are also viable options. Understanding the characteristics of different materials is essential for making an informed decision.

Pressure-treated lumber is a common choice for outdoor furniture due to its resistance to rot and insect infestation. However, pressure-treated lumber can contain chemicals that some individuals may find objectionable. It is important to research and understand the types of treatment used and to follow appropriate safety precautions when working with this material.

Cedar and redwood are naturally durable wood species that are resistant to decay and insects. These woods offer a beautiful natural grain and color and require less chemical treatment than pressure-treated lumber. However, cedar and redwood are typically more expensive than pressure-treated lumber.

Teak is a premium hardwood known for its exceptional durability and resistance to moisture. Teak develops a beautiful silver-gray patina over time, but its high cost can be a deterrent for some builders. Regular oiling can help maintain the original color of teak.

Metal frames can provide strength and stability for garden tables. Aluminum is lightweight and rust-resistant, while steel is stronger but requires a protective coating to prevent corrosion. Metal can be combined with wood or other materials to create unique and modern designs.

Composite lumber is made from recycled plastic and wood fibers. It is resistant to rot, insects, and fading, making it a low-maintenance option for outdoor furniture. Composite lumber is available in a variety of colors and textures, but it can be more expensive than traditional lumber.

Regardless of the material chosen, it is essential to select high-quality lumber that is free from knots, cracks, and other defects. Proper preparation of the materials, including sanding and sealing, will enhance the longevity and appearance of the finished table.

Essential Tools and Techniques for Garden Table Construction

Successful garden table construction relies on the proper use of essential tools and the mastery of fundamental woodworking techniques. Investing in quality tools and practicing basic skills will contribute to a professional-looking finished product.

A circular saw is essential for making straight cuts of lumber. A miter saw can be used for precise angle cuts, which are often required for table legs and aprons. A jigsaw is useful for cutting curves and intricate shapes. Safety precautions, including wearing safety glasses and using appropriate guards, are paramount when operating power tools.

A drill and driver are necessary for assembling the table components with screws and other fasteners. Choose a drill with variable speed settings and a comfortable grip. A countersinking drill bit can be used to create a recess for screw heads, resulting in a flush and professional appearance.

A measuring tape, square, and level are indispensable for ensuring accuracy and precision. Accurate measurements are crucial for achieving a stable and square table. A level is essential for ensuring that the tabletop is flat and the legs are plumb.

Clamps are used to hold pieces of wood together while glue dries or screws are driven. A variety of clamps, including bar clamps, pipe clamps, and spring clamps, can be useful for different applications. Proper clamping ensures strong and durable joints.

Sanding is essential for creating a smooth and even surface. Use sandpaper of varying grits, starting with a coarse grit to remove imperfections and progressing to finer grits for a smooth finish. A power sander can expedite the sanding process, but hand sanding is often necessary for detail work.

Joinery techniques are critical for creating strong and durable connections between the table components. Common joinery techniques include butt joints, lap joints, mortise and tenon joints, and dowel joints. The choice of joinery technique will depend on the design of the table and the desired strength of the connection.

Finishing the table with a sealant, stain, or paint will protect the wood from the elements and enhance its appearance. Choose a finish that is appropriate for outdoor use and follow the manufacturer's instructions carefully. Proper preparation of the surface and application of multiple coats will ensure a long-lasting and attractive finish.

Addressing Common Challenges in Garden Table Woodworking

Despite careful planning and execution, woodworking projects can present unexpected challenges. Understanding common issues and developing strategies to overcome them is essential for a successful outcome.

Wood movement due to changes in humidity and temperature can cause warping, cracking, and joint failure. Choosing appropriate materials and allowing wood to acclimate to the local climate before construction can minimize these problems. Designing the table with expansion and contraction in mind, such as using floating tabletops or allowing for gaps in joints, can also help mitigate the effects of wood movement.

Inaccurate cuts and measurements can result in a table that is not square or stable. Double-check all measurements before cutting and use a square to ensure that pieces are cut at right angles. If a mistake is made, it is often possible to correct it by using shims or adding supports.

Weak or poorly executed joints can compromise the strength and durability of the table. Use high-quality adhesives and fasteners, and ensure that joints are properly aligned and clamped during assembly. If a joint fails, it may be necessary to disassemble the table and rebuild the joint using a stronger technique.

Finishing problems, such as uneven coverage or blistering, can detract from the appearance of the table. Prepare the surface properly by sanding and cleaning it thoroughly before applying the finish. Apply multiple thin coats of finish rather than one thick coat, and allow each coat to dry completely before applying the next.

Insect infestation and rot can damage wooden garden tables over time. Choosing durable wood species and applying a protective finish can help prevent these problems. Regularly inspect the table for signs of damage and take corrective action as needed.

By anticipating potential challenges and developing effective solutions, woodworkers can increase the likelihood of a successful and enjoyable garden table construction project.

Diy Outdoor Dining Table Plan

Easy 10 Person Outdoor Table Rogue Engineer

Patio Table Benches Woodworking Project Woodsmith Plans

Diy Outdoor Farmhouse Table Thrifty And Chic

Diy Outdoor Dining Table Plan

:max_bytes(150000):strip_icc()/38501-f602d5c2a4c84a9e905195400c9c1f4e.jpg?strip=all)

Bistro Patio Table And Stools Woodworking Plan

How To Diy An Outdoor Farmhouse Patio Table

How To Build A Diy Patio Table Family Handyman

:max_bytes(150000):strip_icc()/39367-4f36835646214118a5b0e9ff1c822e11.jpg?strip=all)

Simple Sy Picnic Set Woodworking Plan

Large Dining Table Woodworking Plans

Related Posts