How To Build A Baby Changing Table Dresser

Combining the storage capacity of a dresser with the functionality of a changing table, a baby changing table dresser offers a practical and space-saving solution for nurseries. Constructing one independently allows for customization to match specific aesthetic preferences, spatial limitations, and storage requirements. This article outlines the steps involved in building a durable and safe changing table dresser.

Prior to commencing construction, meticulous planning and preparation are essential. This includes determining the overall dimensions of the dresser, selecting appropriate materials, acquiring necessary tools, and ensuring a dedicated workspace.

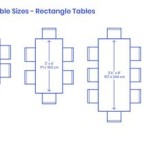

The design should consider the age and weight of the baby, ensuring the changing surface is at a comfortable height for the caregiver to prevent back strain. Standard changing table heights typically range from 36 to 43 inches. The width and depth of the changing area should also accommodate a standard changing pad, generally around 16-17 inches wide and 30-32 inches long. The dresser itself can be customized based on available space and desired storage capacity, typically incorporating drawers of varying sizes.

Material selection is critical for safety and longevity. Solid wood, such as pine, poplar, or oak, offers durability and stability. Alternatively, plywood or MDF (Medium Density Fiberboard) can be used for certain components, but ensure they are formaldehyde-free and CARB compliant to minimize potential health risks. All materials should be sanded smooth to eliminate splinters or rough edges.

The following tools will be required: measuring tape, pencil, safety glasses, dust mask, circular saw or table saw, miter saw (optional), drill with various drill bits, screwdriver (or drill with screwdriver bits), sander, wood glue, clamps, level, and a stud finder (for wall anchoring).

Safety is paramount throughout the construction process. Wearing safety glasses and a dust mask is crucial when cutting or sanding wood to protect eyes and lungs. All power tools should be used according to the manufacturer's instructions. A stable and well-lit workspace is also important to prevent accidents.

Designing and Cutting the Dresser Components

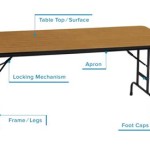

The initial step involves creating a detailed cut list based on the planned dimensions. This list specifies the dimensions of each component, including the dresser's top, bottom, sides, back, drawer fronts, drawer sides, drawer backs, drawer bottoms, and any internal dividers or shelving.

The dresser carcass, consisting of the top, bottom, and sides, forms the structural foundation. These pieces can be cut from solid wood or plywood. Precise measurements and accurate cuts are crucial for a square and stable dresser. Use a circular saw or table saw for straight cuts, ensuring the blade is sharp and the wood is securely supported.

The back panel can be made from plywood or a thinner sheet of MDF. It provides additional stability to the dresser and prevents it from racking. The back panel can be attached using screws and wood glue.

Drawer components require careful cutting and assembly. Drawer fronts, sides, backs, and bottoms should be cut to the specified dimensions. The drawer bottom is typically made from a thin sheet of plywood or MDF and is fitted into grooves cut into the drawer sides and front.

Once all pieces are cut, dry-fitting the components before applying glue and fasteners is recommended. This allows for identifying and correcting any discrepancies in measurements or cuts before they become permanent.

The changing table component is essentially an extension of the dresser top. This can be a separate piece of wood attached to the top, or an integrated raised edge built into the design. The raised edge should be high enough to prevent the baby from rolling off the changing pad, typically 4-6 inches.

Assembling the Dresser and Changing Table

Assembly begins with the dresser carcass. Apply wood glue to the edges of the bottom panel and attach the side panels using clamps and screws. Ensure the sides are flush with the bottom panel and that the assembly is square. Repeat this process for the top panel, ensuring it is also flush and square.

The back panel is then attached to the assembled carcass. Apply wood glue to the edges of the back panel and attach it to the back of the dresser using screws. The back panel should be flush with the edges of the dresser and securely fastened.

Drawer assembly involves gluing and screwing the drawer sides, front, and back together. The drawer bottom is then inserted into the grooves. Clamps should be used to hold the drawer components together while the glue dries. Drawer slides can be installed after the drawers are assembled. The slides should be mounted according to the manufacturer's instructions, ensuring they are aligned correctly for smooth drawer operation.

The changing table component is attached to the dresser top using wood glue and screws. Ensure the changing table is securely fastened and that the surface is level. If constructing a raised edge, attach the side and back pieces using wood glue and screws, ensuring they are aligned properly and create a secure barrier.

After the glue has dried, all surfaces should be sanded smooth to remove any imperfections or rough edges. Start with a coarser grit sandpaper and gradually move to a finer grit for a smooth finish.

Consider incorporating features like soft-close drawer slides to prevent fingers from getting pinched and increasing the overall lifespan of the dresser.

Finishing and Safety Considerations

The finishing process involves applying a sealant, stain, or paint to protect the wood and enhance its appearance. Choose a finish that is non-toxic and safe for use around babies. Water-based finishes are generally a safer option than oil-based finishes. Follow the manufacturer's instructions for application and drying times.

Before applying the finish, ensure all surfaces are clean and free of dust. Apply the finish in thin, even coats, allowing each coat to dry completely before applying the next. Sand lightly between coats to achieve a smooth finish.

Once the finish is dry, install drawer pulls or knobs. Choose hardware that is smooth and free of sharp edges. Ensure the hardware is securely fastened to prevent it from coming loose and posing a choking hazard.

Securing the changing table dresser to the wall is crucial for preventing tip-over accidents. Use a stud finder to locate wall studs and attach the dresser to the studs using appropriate hardware, such as L-brackets and screws. Follow the manufacturer's instructions for the hardware and ensure the dresser is securely anchored to the wall.

Always use a changing pad with safety straps to secure the baby during diaper changes. Never leave a baby unattended on the changing table. Keep all supplies, such as diapers, wipes, and lotions, within easy reach but out of the baby's reach. Regularly inspect the changing table dresser for any signs of wear or damage and make any necessary repairs promptly.

Consider adding rounded edges to the changing table top and any exposed corners to minimize the risk of injury. Regularly inspect all screws and fasteners to ensure they remain tight.

Building a baby changing table dresser is a rewarding project that allows for customization and cost savings. By following these steps and prioritizing safety at every stage, it is possible to create a functional and beautiful piece of furniture that will serve the family well for years to come.

Diy Changing Table Dresser Kreg Tool

Free Baby Changing Table Woodworking Plans

Diy Simple Vintage Inspired Dresser Free Woodworking Plans

Baby Changing Table Topper Ana White

Nursery Changing Station Diy With Storage Jenna Sue Design

Baby Changing Table Topper Ana White

Free Baby Changing Table Woodworking Plans

5 Drawer Dresser Changing Table Her Tool Belt

Free Baby Changing Table Woodworking Plans

Nursery Changing Station Diy With Storage Jenna Sue Design

Related Posts