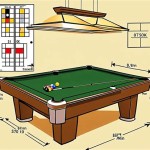

Billiard Table Ball Return System: Functionality and Variations

A billiard table ball return system is an integral component of modern pool tables, designed to streamline gameplay by automatically collecting and returning the balls to a designated location after they have been pocketed. This system eliminates the need for players to manually retrieve balls from the pockets, enhancing the flow of the game and minimizing interruptions. The complexity and design of ball return systems can vary, encompassing different mechanical principles and materials. This article will explore the functionality, variations, and key considerations surrounding billiard table ball return systems.

The primary function of a ball return system is to guide pocketed balls from the individual pockets located around the perimeter of the table to a centralized collection area, typically situated at one end of the table. This collection area is designed for easy access, allowing players to quickly rack the balls for the next game. The implementation of a ball return system significantly contributes to the ease of use and overall enjoyment of the game, particularly in commercial settings or during extended play sessions. Without a ball return system, players would be required to walk around the table repeatedly to collect the balls, leading to fatigue and decreased efficiency.

The efficiency and reliability of a ball return system are crucial factors to consider when evaluating a pool table. A well-designed system should minimize the likelihood of balls becoming jammed or detoured, ensuring a smooth and consistent return process. The materials used in the construction of the system also play a critical role in its durability and longevity. Typically, these systems are constructed using a combination of durable plastics, metals, and fabrics.

Gravity-Fed Ball Return Systems

One of the most common types of ball return systems relies on gravity to move the balls from the pockets to the collection area. These systems typically consist of a series of sloped channels or tracks that are strategically positioned beneath the playing surface of the table. When a ball is pocketed, it falls into the corresponding pocket liner and is directed into these channels. The slope of the channels, combined with the force of gravity, causes the ball to roll along the track until it reaches the centralized ball return box.

The design of the channels is crucial for ensuring the smooth and efficient movement of the balls. The channels need to be wide enough to accommodate the balls without causing them to jam, but also narrow enough to prevent the balls from rolling off the track. The slope of the channels also needs to be carefully calibrated to provide sufficient momentum for the balls to reach the collection area without requiring excessive height, which could affect the overall table design.

The construction of gravity-fed ball return systems often involves the use of durable plastics, such as ABS (Acrylonitrile Butadiene Styrene) or PVC (Polyvinyl Chloride). These materials are lightweight, resistant to impact, and can be easily molded into complex shapes. Metal components, such as steel or aluminum, may also be used to provide additional structural support and durability. The interior surfaces of the channels are often lined with fabric, such as felt or nylon, to reduce noise and friction as the balls roll along the track.

The key advantage of gravity-fed ball return systems is their simplicity and reliability. They require no electrical power or complex mechanical components, making them relatively low-maintenance. However, they can be somewhat bulky and may require more vertical space within the table frame compared to other types of systems. The angle of the table legs and overall construction must compensate for the additional weight of the ball return system underneath the playing surface.

Magnetic Ball Return Systems

Magnetic ball return systems represent a more sophisticated approach to ball retrieval. These systems utilize magnetic fields to propel the balls from the pockets to the collection area. Each ball is typically embedded with a small magnet, which interacts with a series of electromagnets or permanent magnets positioned along the ball return path. When a ball is pocketed, the magnets are activated, creating a force that pulls or pushes the ball along the track.

The advantage of magnetic ball return systems is that they can be more compact and require less vertical space compared to gravity-fed systems. This is because the magnetic force can be used to move the balls along a horizontal or even slightly upward path, eliminating the need for a significant slope. This allows for more design flexibility and can result in a table with a lower profile. Furthermore, magnetic systems can offer a quieter operation compared to the rumble and clatter associated with some gravity-fed systems.

The complexity of magnetic ball return systems also presents some challenges. They require a power source to operate the electromagnets, and the system's performance can be affected by the strength and placement of the magnets. The cost of manufacturing magnetic ball return systems is generally higher due to the specialized components and more intricate engineering involved.

The use of magnets also introduces potential maintenance concerns. Over time, the magnets may lose their strength, or the electronic components may fail. It is crucial that the magnets are shielded and properly insulated to prevent interference with other electronic devices or potential harm to users. The electromagnetic fields can be influenced by external electrical components, so a dedicated power source is usually required.

Chute and Ramp Ball Return Systems

Chute and ramp systems represent another variation in ball return technology. These systems typically incorporate a series of chutes and ramps to guide the balls from the pockets to the collection area. The chutes are generally constructed from molded plastic or metal and are designed to direct the balls into a central pathway. The ramps provide a smooth transition between different sections of the return path.

The design of the chutes and ramps is critical for ensuring the smooth and uninterrupted flow of the balls. The angles and curves of the components must be carefully calculated to prevent the balls from becoming jammed or detoured. The materials used in the construction of the system must be durable and resistant to wear and tear.

Chute and ramp systems often incorporate a combination of gravity and momentum to move the balls along the return path. The balls may initially be propelled by gravity as they fall from the pockets into the chutes. Once in the chutes, they gain momentum as they travel along the sloping path. The ramps are used to redirect the balls and maintain their momentum as they transition to different sections of the system.

These systems often present a balance between the simplicity of gravity fed types and the complexity of magnetic types. They can be made more compact than gravity fed systems, but do not require electricity. Furthermore, there will be slightly less rumble compared to a gravity-fed design. However, the complexity of ensuring a jam-resistant design can make these more expensive than straight gravity-fed systems.

Materials and Construction Considerations

The materials used in the construction of a ball return system play a significant role in its performance, durability, and noise level. Common materials include plastics, metals, and fabrics. The choice of material depends on factors such as cost, weight, strength, and resistance to wear and tear.

Durable plastics, such as ABS and PVC, are widely used for the channels, chutes, and other components of the ball return system. These materials are lightweight, relatively inexpensive, and can be easily molded into complex shapes. Metal components, such as steel and aluminum, may be used to provide additional structural support and rigidity.

Fabrics, such as felt or nylon, are often used to line the interior surfaces of the channels and chutes to reduce noise and friction. The fabric also helps to protect the balls from scratches and damage as they move along the return path. The choice of fabric depends on factors such as cost, durability, and sound absorption properties.

The construction of the ball return system must also be carefully considered to ensure its long-term reliability. The components must be securely fastened together to prevent them from coming loose or shifting over time. The system must also be designed to withstand the constant impact of the balls without becoming damaged or deformed.

Furthermore, the design should allow for easy access to make repairs if issues are found. Most manufacturers will provide some level of limited warranty with their billiard tables, but after the warranty period, the owner must make any repairs. Easy access can keep repair costs low, and increase enjoyment of the game. The materials also need to be non-reactive to standard cleaning materials, as cleaning the table will inevitably require cleaning the ball return system.

Finally, the overall quality of the table construction and the quality of the ball return system are intricately linked. A poorly built table will be more prone to having issues with its return system, as the angles and design will be slightly off from what it should be. Conversely, it is difficult to put a high-quality ball return system into a low-quality table. While it may work, it will probably fail relatively quickly due to a less-than-ideal implementation.

Ball Return System Eliminator 7 And 8 Ortmann Billiards Com Billiard For Tables Accessoires

Pool Table Drop Pockets Vs Ball Return Home Leisure Direct

Antique Pool Table Ball Return Make

Replace Or Repair A Victor Pool Table Ball Return System

Pool Table Ball Return Track G03 01 Hehder

How Does The Ball Return Work On A Coin Operated Pool Table Howstuffworks

Result For Pool Table Ball Return Diy Billiard

Ball Return System With Pockets Sku Qgull Et Buy Now

Billards Montfort Lewis Inox Stainless Steel Luxury Pool Table

Ball Return System Tube Mueller S Billiard Dart Supplies