Choosing the Right Clear Coat for Your Wood Table Top

A wood table top, whether showcasing the natural beauty of the grain or serving as the centerpiece of a dining set, requires a durable and aesthetically pleasing finish. The clear coat applied to a wood table top serves a crucial protective function, shielding the wood from scratches, stains, moisture, and UV damage. Furthermore, it enhances the visual appeal, highlighting the wood's character and providing the desired level of sheen. Selecting the appropriate clear coat requires careful consideration of factors such as the table's intended use, the type of wood, the desired aesthetic, and the application environment.

Several clear coat options are available, each with distinct properties and application requirements. These include polyurethane, lacquer, varnish, water-based acrylics, and epoxy resins. Understanding the characteristics of each type is essential for making an informed decision that results in a long-lasting and beautiful finish.

Understanding Different Types of Clear Coats

Different clear coat types have distinct chemical compositions that contribute to their specific properties, advantages, and disadvantages. These variations influence their durability, resistance to wear and tear, ease of application, and overall aesthetic appearance. A thorough understanding of these differences is critical for selecting the most suitable option for a specific wood table top project.

Polyurethane: Polyurethane clear coats are known for their exceptional durability and resistance to abrasion, chemicals, and moisture. They are available in both oil-based and water-based formulations. Oil-based polyurethanes tend to offer greater durability and a richer, amber hue that can enhance the wood's warmth. However, they also release higher levels of volatile organic compounds (VOCs) and require a longer drying time. Water-based polyurethanes are lower in VOCs, dry faster, and clean up easily with water, but might not be as durable as their oil-based counterparts. Polyurethane is a suitable option for table tops that experience heavy use, such as dining tables or work surfaces, due to its ability to withstand scratches, spills, and frequent cleaning.

Lacquer: Lacquer is a fast-drying clear coat that produces a smooth, glossy finish. It is available in various sheens, from matte to high-gloss. Lacquer is known for its ease of application and ability to be applied in multiple thin coats, resulting in a build-up of protection without compromising the clarity of the underlying wood grain. However, lacquer is less resistant to moisture and chemicals than polyurethane. It is often used on furniture that is not subjected to heavy use or frequent exposure to liquids. It's important to note that many lacquers contain high VOCs and should be applied in a well-ventilated area.

Varnish: Varnish is a traditional clear coat that offers good durability and water resistance. It is typically oil-based and provides a warm, amber tone to the wood. Varnish is slower drying than lacquer or polyurethane but offers a robust finish. Historically, varnish was a common choice for furniture and marine applications due to its ability to protect against the elements. While still used, varnish is increasingly being superseded by polyurethane due to the latter's superior durability and resistance to chemicals.

Water-Based Acrylics: Water-based acrylic clear coats are gaining popularity due to their low VOC content, ease of application, and quick drying time. They provide a clear, non-yellowing finish that allows the natural color of the wood to shine through. While generally less durable than polyurethane, advancements in water-based acrylic technology have led to significant improvements in their scratch and chemical resistance. They are a good choice for projects where environmental considerations are paramount or where a clear, non-yellowing finish is desired.

Epoxy Resin: Epoxy resin is a two-part system that, when mixed, creates a very hard, durable, and waterproof finish. It is ideal for creating a thick, glass-like surface that can encase objects or create stunning visual effects. Epoxy resin is highly resistant to scratches, chemicals, and heat. However, it can be costly, requires careful mixing and application to avoid bubbles, and can be prone to yellowing over time if not properly formulated with UV inhibitors. Epoxy resin is often used for bar tops, river tables, and other projects where a high-gloss, durable, and decorative finish is desired.

Factors to Consider When Choosing a Clear Coat

The ideal clear coat for a wood table top depends on a range of factors beyond just the type of coating. The table's intended use, the wood species, the desired aesthetic, and the application environment all play a significant role in the selection process.

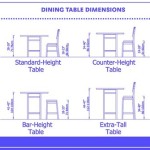

Intended Use: The intended use of the table is a primary consideration. A dining table that will be subjected to frequent spills, hot dishes, and cleaning requires a more durable and chemical-resistant finish than a purely decorative side table. For high-use surfaces, polyurethane or epoxy resin are generally preferred. For lower-use surfaces, lacquer or water-based acrylics may suffice.

Wood Species: The type of wood also influences the choice of clear coat. Some woods, such as cherry or walnut, have rich natural colors that can be enhanced by an oil-based clear coat. Lighter woods, such as maple or ash, may benefit from a water-based clear coat that will not yellow over time. The porosity of the wood also matters. More porous woods may require multiple coats of clear coat or a wood sealer to prevent the finish from being absorbed unevenly.

Desired Aesthetic: The desired aesthetic is another important factor. Do you want a high-gloss finish that reflects light or a matte finish that minimizes glare? Do you want to enhance the wood's natural color or maintain its original tone? The choice of clear coat will significantly impact the final appearance of the table. Lacquer is known for its ability to achieve a high-gloss finish, while water-based acrylics provide a clear, matte finish. Oil-based clear coats tend to add warmth and depth to the wood's color.

Application Environment: The application environment also plays a role in the selection process. Some clear coats, such as lacquer and oil-based polyurethanes, contain high levels of VOCs and should be applied in a well-ventilated area. Water-based clear coats are a safer option for those concerned about VOCs. The temperature and humidity of the environment can also affect the drying time and curing process of the clear coat. It is important to follow the manufacturer's instructions carefully to ensure a proper application.

Preparation and Application Techniques

The success of any clear coat application hinges on proper preparation and application techniques. Regardless of the type of clear coat chosen, thorough surface preparation, appropriate application methods, and adherence to drying and curing times are crucial for achieving a professional-looking and long-lasting finish.

Surface Preparation: The first step in preparing a wood table top for clear coat is to ensure that the surface is clean, smooth, and free of any imperfections. This typically involves sanding the wood with progressively finer grits of sandpaper, starting with a coarser grit to remove any existing finish or blemishes and finishing with a fine grit to create a smooth surface. After sanding, it is important to remove all dust and debris with a tack cloth or vacuum cleaner. Any oil or grease should be removed with a solvent-based cleaner. If the wood is stained, ensure the stain is completely dry and cured before applying the clear coat.

Application Methods: The clear coat can be applied using a variety of methods, including brushes, rollers, and spray guns. The choice of application method will depend on the type of clear coat, the size and shape of the table top, and the desired level of finish. Brushes are best for applying clear coat to small or intricate areas, while rollers are more efficient for covering large, flat surfaces. Spray guns provide the most even and consistent finish but require more skill and equipment. When using a brush or roller, apply thin, even coats of clear coat, overlapping each stroke slightly to avoid streaks or drips. When using a spray gun, maintain a consistent distance and speed to ensure an even application.

Drying and Curing Times: After applying the clear coat, it is important to allow it to dry and cure completely before using the table. Drying times will vary depending on the type of clear coat, the temperature and humidity of the environment, and the thickness of the coat. Follow the manufacturer's instructions carefully to determine the appropriate drying time. Curing is the process by which the clear coat hardens and becomes more durable. Curing times are typically longer than drying times and can range from several days to several weeks. Avoid placing heavy objects on the table or exposing it to moisture or chemicals until the clear coat has fully cured.

Selecting the right clear coat for a wood table top involves a comprehensive assessment of various factors. Evaluating the types of clear coats, understanding the factors related to selection, and mastering the preparation and application are key. Ultimately, the right choice translates to a durable, beautiful, and long-lasting finish that protects the wood and enhances its inherent beauty.

Table Top Stain Clear Coat Espresso Gloss Polyurethane Farmhouse Series 4 Of 5

The Best Clear Coat For Painted Wood 2024 Tested Reviewed

How To Use Clear Coat Protect Painted Table Tops High Traffic Furniture Country Chic Paint

Fast Hardening Heat Resistant Clear Coat For Wood China Resin Made In Com

Table Top Tabletop Ultraclear

Resin Colors Home Of Art Tree Creations Pigment Paste Pearls And Metal Powders To Color High Quality Pigments Strong For A Little Will Go Long

Ultra Clear Bar Top Table Wood Resin China And

Wood Clear Coat For Outdoor Use

Types Of Wood Finishes The Home Depot

Timberland Table Tops Clear Coat All Care Seating