The Comprehensive Cost to Refinish a Kitchen Table and Chairs

Refinishing a kitchen table and its accompanying chairs is a viable option for homeowners looking to revitalize their dining space without incurring the expense of purchasing entirely new furniture. The cost associated with this undertaking, however, varies significantly based on several factors. These factors encompass the size and complexity of the furniture, the materials used in their construction, the chosen refinishing method, and whether the homeowner undertakes the project as a DIY endeavor or hires professional refinishers.

Understanding the various cost components is crucial for informed decision-making. This article will delve into the detailed breakdown of expenses involved, examining both the materials and labor costs, and providing insights into how different choices can impact the overall budget. By carefully considering these aspects, homeowners can accurately estimate the cost of refinishing their kitchen table and chairs and determine whether it aligns with their financial constraints and aesthetic preferences.

Material Costs for Refinishing

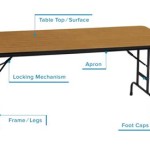

The foundation of any refinishing project lies in the quality and quantity of materials used. These materials contribute substantially to the total cost and directly impact the final appearance and durability of the refinished furniture. The specific materials required can vary depending on the existing finish, the desired outcome, and the condition of the table and chairs.

Stripping Agents: The initial step in refinishing typically involves removing the existing finish. This process necessitates the use of stripping agents, which are available in various formulations, including chemical strippers, heat guns, and sanding methods. Chemical strippers are generally priced per gallon and can range from $20 to $50, depending on the brand and strength. The quantity needed depends on the size of the table and chairs and the thickness of the existing finish. Heat guns, an alternative to chemical strippers, represent a one-time purchase, typically costing between $30 and $100 for a quality tool, but are less effective on certain types of finishes. Sanding, although labor-intensive, requires sandpaper of varying grits, costing approximately $10 to $30 depending on the quantity and type of sandpaper purchased.

Sandpaper: Sandpaper is indispensable for preparing the surface for refinishing. Different grits are used for different stages of the process, starting with coarser grits to remove imperfections and transitioning to finer grits to achieve a smooth surface. A variety pack containing multiple grits is often the most cost-effective option. The cost typically ranges from $10 to $30, depending on the number of sheets and the quality of the sandpaper.

Wood Filler: Any imperfections, such as scratches, dents, or gouges, must be repaired before applying the new finish. Wood filler is used to fill these imperfections and create a smooth, even surface. The cost of wood filler ranges from $5 to $20 per container, depending on the size and type. Epoxy-based fillers, known for their durability, may be more expensive than traditional wood fillers.

Primer: Primer is applied after sanding and filling to create a uniform surface and improve the adhesion of the topcoat. Primers are generally priced per gallon and can range from $15 to $40, depending on the type and brand. Oil-based primers offer excellent adhesion and are suitable for most surfaces, while water-based primers are low-VOC and environmentally friendly.

Stain or Paint: The choice between stain and paint depends on the desired aesthetic. Stain enhances the natural wood grain, while paint provides a solid color finish. Stain costs range from $20 to $50 per quart, while paint prices vary widely based on the type and quality, ranging from $20 to $60 per gallon. Consider the number of coats needed, as this will affect the total quantity required.

Topcoat (Sealer): A topcoat, also known as a sealer, protects the finish and adds durability. Common topcoat options include polyurethane, lacquer, and varnish. Polyurethane is a popular choice due to its durability and water resistance. The cost of topcoats ranges from $25 to $60 per quart, depending on the type and brand.

Applicators (Brushes, Rollers, Spray Equipment): Applying the finish requires brushes, rollers, or spray equipment. High-quality brushes and rollers can cost between $10 and $50 each. Spray equipment, such as HVLP (High Volume Low Pressure) sprayers, can range from $100 to $500, but provide a more even and professional finish. Consider the ease of cleaning and maintenance when selecting applicators.

Safety Equipment: Safety should be a paramount consideration during the refinishing process. Essential safety equipment includes gloves, eye protection, and a respirator. Gloves protect the hands from chemicals and solvents, while eye protection prevents splatters and debris from entering the eyes. A respirator is crucial for protecting the lungs from harmful fumes, especially when using chemical strippers or spray finishes. The cost for these items can range from $20 to $50.

Labor Costs for Professional Refinishing

Hiring professional refinishers offers the advantage of expertise and efficiency, but it also represents a significant cost component. Labor costs can vary depending on the complexity of the job, the location of the service provider, and the level of experience of the refinishers. It is essential to obtain multiple quotes from different refinishers and carefully evaluate their proposals before making a decision.

Hourly Rates vs. Flat Fees: Refinishers often charge either an hourly rate or a flat fee for the entire project. Hourly rates can range from $50 to $100 per hour, depending on the location and experience of the refinisher. Flat fees, on the other hand, provide a fixed price for the entire job, which can offer more predictability in budgeting. However, it is crucial to ensure that the flat fee covers all aspects of the refinishing process, including stripping, sanding, repair, and finishing.

Complexity of the Project: The complexity of the refinishing project directly impacts the labor costs. Intricate designs, ornate carvings, or significant damage necessitate more time and skill, resulting in higher labor charges. Simple, straightforward refinishing projects will typically be less expensive than those requiring extensive repairs or intricate finishing techniques.

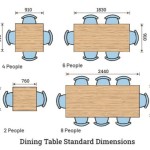

Number of Pieces: The number of chairs and the size of the table influence the total labor costs. Refinishing multiple chairs will naturally take more time than refinishing a single chair. Similarly, a large dining table will require more effort and materials than a small side table. Refinishers often provide discounts for refinishing multiple pieces of furniture simultaneously.

Transportation Costs: Some refinishers offer on-site refinishing services, while others require the furniture to be transported to their workshop. If transportation is required, it can add to the overall cost. Transportation costs may be included in the flat fee or charged separately, depending on the service provider. Consider the convenience and potential risk of damage during transportation when evaluating this aspect of the cost.

Additional Services: Additional services, such as upholstery repair or replacement, can further increase the labor costs. If the chairs require new fabric or padding, this will add to the overall expense. Discuss any additional service requirements with the refinisher and obtain a detailed estimate before proceeding.

Geographic Location: Labor costs vary significantly depending on the geographic location. Refinishers in major metropolitan areas typically charge higher rates than those in smaller towns or rural areas. Consider the cost of living in your area when evaluating the quotes from different refinishers.

DIY vs. Professional Refinishing: A Cost Comparison

The decision to undertake a DIY refinishing project or hire professional refinishers is a critical factor in determining the overall cost. DIY refinishing can save significantly on labor costs, but it requires time, effort, and a certain level of skill. Professional refinishing offers the advantage of expertise and efficiency, but it comes at a higher price.

DIY Cost Factors: The primary cost factors for DIY refinishing are the materials and tools required. As detailed in the "Material Costs" section, the cost of stripping agents, sandpaper, wood filler, primer, stain or paint, topcoat, applicators, and safety equipment can add up to a significant investment. Additionally, certain tools, such as a heat gun or HVLP sprayer, may require a substantial upfront investment. However, these tools can be reused for future projects, making them a worthwhile investment for those who frequently engage in DIY projects.

Professional Cost Factors: As detailed in the "Labor Costs" section, the primary cost factors for professional refinishing are the hourly rates or flat fees charged by the refinishers. These costs can vary significantly depending on the complexity of the project, the number of pieces, the transportation requirements, and the geographic location. In addition to the labor costs, professional refinishers may also charge a markup on the materials used.

Hidden Costs: Both DIY and professional refinishing projects can involve hidden costs. In DIY projects, these may include the cost of mistakes, such as applying the wrong finish or damaging the furniture. In professional refinishing projects, these may include unexpected repairs or additional services that were not initially included in the estimate. Contingency planning is essential to mitigate the impact of potential hidden costs.

Skill Level and Time Commitment: DIY refinishing requires a certain level of skill and a significant time commitment. The process can be time-consuming, especially for beginners. It is essential to assess your skill level and available time before embarking on a DIY refinishing project. Professional refinishers offer the advantage of expertise and efficiency, completing the project in a timely manner with a high-quality finish.

Long-Term Value: Consider the long-term value of the refinished furniture when making the decision between DIY and professional refinishing. A professionally refinished piece of furniture may have a higher resale value than a DIY refinished piece. Additionally, a professionally refinished piece of furniture is likely to be more durable and require less maintenance over time.

Ultimately, the choice between DIY and professional refinishing depends on individual circumstances, including budget constraints, skill level, time availability, and desired outcome. Carefully weigh the pros and cons of each option before making a decision.

How Much Does It Cost To Refinish A Dining Table Salpeck S

How Much Does It Cost To Refinish A Dining Table Salpeck S

Refinishing My Dining Table And Chairs Nashville Wife

Factors That Affect The Cost Of Furniture Refinishing

How Much Does It Cost To Refinish Kitchen Cabinets Broke And Chic

Refinishing My Dining Table And Chairs Nashville Wife

Farmtable Makeover Using Miss Mustard Seed Milk Paint Reinvented Delaware

Dining Table Set Buy In Prayagraj At Best Woodenstreet

True Furniture Sheesham Wood Dining Table For Living Room Set Of 6 Chairs Mahogany Finish Solid Seater At Best In Ratangarh

Rite Furniture