The Allure and Craft of Custom Ping Pong Tables

The game of ping pong, also known as table tennis, has transcended its humble beginnings to become a global sport and a popular recreational activity. Beyond the standard equipment, the desire for personalized sports experiences has spurred the demand for custom ping pong tables. These tables offer a distinct blend of functionality and aesthetics, allowing individuals and organizations to showcase their unique style and brand identity. This article explores the various facets of custom ping pong tables, examining the design possibilities, material choices, construction considerations, and the benefits they offer.

Design Possibilities: Tailoring the Table to Individual Preferences

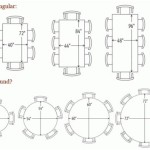

The customization process begins with design. Unlike mass-produced tables, custom ping pong tables offer limitless possibilities for tailoring the appearance to suit individual preferences and spatial requirements. This extends to the table's shape, size, and visual features.

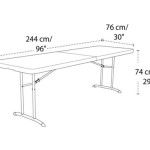

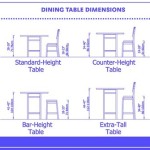

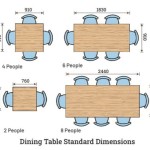

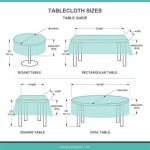

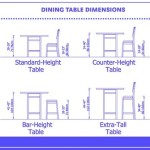

Standard ping pong tables adhere to an international regulation size of 9 feet long, 5 feet wide, and 30 inches high. While these dimensions ensure fair gameplay, custom orders can deviate slightly to accommodate smaller spaces or create an oversized statement piece. For instance, a client with limited square footage might opt for a slightly shorter or narrower table. Conversely, a games room with ample space could accommodate a larger table that serves as a focal point.

Surface graphics and finishes play a crucial role in the custom design process. While traditional ping pong tables often feature a standard green or blue surface, customized versions can incorporate logos, patterns, artwork, or even photographic images. These graphics can be applied using various techniques, including direct printing, vinyl wraps, or hand-painted designs. The choice of finish also impacts the table's appearance and playability. Matte finishes minimize glare, while glossy finishes offer a sleek, modern look. The finish must be durable and provide the appropriate level of friction for optimal ball bounce.

Beyond the playing surface, the base and frame of the table are also ripe for customization. Different materials, such as wood, metal, or even concrete, can be used to construct the base, each offering a unique aesthetic. The shape and style of the legs can also be modified to match the overall design theme. For example, a contemporary design might feature sleek metal legs, while a rustic design could incorporate reclaimed wood.

Unique features can be integrated into the table's design to enhance its functionality and visual appeal. These might include built-in storage for paddles and balls, LED lighting that illuminates the playing surface, or even integrated scoring systems. Some custom tables incorporate interactive elements, such as electronic games or virtual reality integration, blurring the lines between traditional ping pong and modern technology.

Material Choices: Balancing Aesthetics, Durability, and Performance

The materials used in the construction of a custom ping pong table significantly impact its aesthetics, durability, and performance. Each material possesses unique properties that contribute to the overall quality and feel of the table.

The playing surface is typically made of wood, with medium-density fiberboard (MDF) being a common choice due to its smooth, consistent surface and affordability. However, higher-end custom tables may utilize solid wood or specialized composite materials that offer improved bounce characteristics and durability. The thickness of the playing surface is also a critical factor, with thicker surfaces generally providing a more consistent and predictable ball bounce.

The base and frame of the table can be constructed from a variety of materials, including wood, metal, and concrete. Wood offers a classic, warm aesthetic and can be easily customized with various finishes and stains. Metal provides a more modern, industrial look and is known for its strength and durability. Concrete offers a unique, contemporary aesthetic and is particularly well-suited for outdoor use due to its weather resistance. The choice of material depends on the desired aesthetic, the intended use of the table, and the budget.

The finish applied to the playing surface also plays a crucial role in its performance. The finish should be smooth and even, providing a consistent ball bounce. It should also be durable and resistant to scratches and wear. Common finishes include polyurethane, lacquer, and varnish. The choice of finish depends on the desired level of gloss, the durability requirements, and the ease of application.

The net, typically made of fabric or synthetic materials, can also be customized to match the overall design of the table. The net can be printed with logos, patterns, or artwork. The posts that support the net can be made of metal, wood, or plastic and can be designed to complement the table's base and frame.

Hardware components, such as hinges, screws, and latches, should be of high quality to ensure the table's structural integrity and longevity. Stainless steel hardware is a good choice for outdoor tables due to its corrosion resistance. The hardware should be chosen to match the overall aesthetic of the table and should be installed securely to prevent loosening or failure.

Construction Considerations: Precision, Stability, and Playability

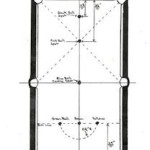

The construction of a custom ping pong table requires precision and attention to detail to ensure stability, playability, and longevity. The table must be level and stable to provide a fair playing surface. The ball bounce must be consistent and predictable. And the table must be durable enough to withstand regular use.

The first step in the construction process is to create a detailed design plan. This plan should include the dimensions of the table, the materials to be used, and the construction methods to be employed. The plan should also include detailed drawings or renderings that illustrate the table's appearance.

Once the design plan is complete, the materials must be carefully selected and prepared. The playing surface should be cut to the correct dimensions and sanded smooth. The base and frame should be constructed according to the design plan, ensuring that all joints are strong and secure.

The playing surface must be attached to the base and frame in a way that ensures it is level and stable. This may involve using shims or other leveling devices to compensate for any imperfections in the floor. The playing surface should be attached securely to prevent it from warping or sagging over time.

The finish should be applied to the playing surface in multiple thin coats, allowing each coat to dry completely before applying the next. The finish should be applied evenly to ensure a consistent ball bounce. Once the finish is dry, it should be lightly sanded to remove any imperfections.

The net and posts should be attached to the table in a way that ensures they are securely in place. The net should be taut and should be positioned at the correct height. The posts should be aligned correctly and should be secured to the table to prevent them from moving.

Quality control is essential throughout the construction process. Each step should be carefully inspected to ensure that it meets the required standards. Any defects should be corrected immediately. The finished table should be thoroughly tested to ensure that it is level, stable, and playable.

Shipping and installation are also important considerations. The table should be carefully packaged to protect it from damage during transit. The installation process should be straightforward and should be carried out by qualified personnel. The table should be leveled and secured in its final location to ensure its stability.

Custom ping pong tables offer a unique blend of functionality and aesthetics. They provide a personalized playing experience while also serving as a statement piece in any home, office, or recreational space. The design possibilities are virtually limitless, allowing individuals and organizations to create a table that reflects their unique style and brand identity. The choice of materials is crucial for ensuring the table's durability, performance, and aesthetic appeal. And the construction process requires precision and attention to detail to ensure that the table is level, stable, and playable. When all of these factors are carefully considered, a custom ping pong table can be a truly exceptional addition to any environment.

Force Luxury Custom High End Ping Pong Table Modern Living Room Orange County By 11 Ravens Houzz

Room Table Walnut Ping Pong 2 Piece Dining Custom For Tennis Wood Singapore

Customisable Outdoor Ping Pong Table Pongo

Ping Pong Table All In One Merchandise

Custom Ping Pong Tables

Man Cave With A Custom Modern Ping Pong Table Contemporary Living Room Los Angeles By 11 Ravens Houzz

Custom Ping Pong Tables

Custom Curly Maple And Pada Ping Pong Table Woodworking Network Diy

Custom Portable Ping Pong Table

Force Luxury Custom High End Ping Pong Table Modern Living Room Orange County By 11 Ravens Houzz