Farm Table Bench Plans: A Comprehensive Guide to Building Your Own Rustic Seating

The enduring appeal of farm tables lies in their simplicity, functionality, and the sense of community they foster. Completing this aesthetic often involves accompanying benches, offering a cohesive and inviting dining or gathering space. Building your own farm table bench allows for customization, cost-effectiveness, and a rewarding sense of accomplishment. This article provides a comprehensive guide to understanding and utilizing farm table bench plans, covering key aspects of design, material selection, construction techniques, and finishing options.

Understanding Farm Table Bench Design Principles

Before embarking on a building project, it's crucial to understand the fundamental design principles that govern the construction of a stable and aesthetically pleasing farm table bench. These principles primarily concern size, proportion, and structural integrity.

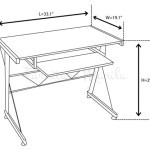

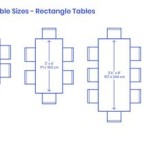

Size and Proportion: The dimensions of the bench should be carefully considered in relation to the accompanying table. Ideally, the bench should be approximately 10-12 inches shorter than the table's length, allowing space for movement and preventing the bench from protruding beyond the table's ends. The height of the bench is equally important. A comfortable seating height generally falls between 17-19 inches from the floor. The width of the bench can vary depending on the desired aesthetic and number of intended users, but a width of 12-16 inches is generally adequate.

When determining the dimensions, consider the intended use. If the bench will primarily be used for dining, adhering to standard dining seat heights is essential. If the bench is intended for more casual seating, such as in an entryway or mudroom, the height can be adjusted slightly to suit the space. Always measure the height of your existing table and plan your bench height accordingly. A lower bench is preferable to a bench that's too high.

Structural Integrity: A well-designed farm table bench must be structurally sound to withstand regular use. This is achieved through proper joint selection, adequate material thickness, and the incorporation of support structures. Common joint types used in bench construction include mortise and tenon joints, lap joints, and pocket screw joints. The choice of joint depends on the skill level of the builder and the desired aesthetic. Mortise and tenon joints offer superior strength and a traditional look, but require more advanced woodworking skills. Lap joints provide a good balance of strength and ease of construction. Pocket screw joints are the simplest to execute and are suitable for smaller, less demanding benches.

Regardless of the joint type, adequate material thickness is crucial. The bench top should be thick enough to prevent sagging under weight. A minimum thickness of 1.5 inches is generally recommended for solid wood bench tops. The legs should also be substantial enough to provide stability. At least 2.5 inches for leg thickness is recommended. Strengthening the bench with aprons or stretchers is another way to boost its structural integrity. These elements connect the legs and provide additional support for the bench top.

Material Selection for Farm Table Benches

The choice of materials significantly influences the appearance, durability, and cost of the farm table bench. While solid wood is the most common and aesthetically desirable option, alternative materials such as reclaimed wood and engineered wood products can also be used.

Solid Wood: Solid wood offers natural beauty, durability, and the potential for refinishing. Common wood species used for farm table benches include pine, oak, maple, and walnut. Pine is a cost-effective option that can be easily stained or painted. Oak is a durable hardwood with a distinctive grain pattern. Maple is a hard, dense wood that provides a smooth, uniform surface. Walnut is a premium hardwood with a rich, dark color and elegant grain.

When selecting solid wood, it's essential to consider the moisture content of the wood. Wood that is too wet will shrink and warp as it dries, leading to structural problems. Kiln-dried wood is preferred, as it has been dried to a stable moisture content. It's also important to inspect the wood for any defects, such as knots, cracks, or insect damage. Select boards that are straight and free of significant imperfections.

Reclaimed Wood: Reclaimed wood offers a unique character and a sustainable building option. This type of wood comes from old barns, factories, and other structures. Reclaimed wood often has a weathered appearance, nail holes, and other imperfections that add to its rustic charm. However, it's important to carefully inspect reclaimed wood for structural integrity and potential contaminants. Metal detectors can be used to locate hidden nails or screws. Power washing or wire brushing can remove dirt and debris.

Engineered Wood Products: Engineered wood products, such as plywood and MDF (medium-density fiberboard), can be used in farm table bench construction, particularly for the bench top. These materials are less expensive than solid wood and offer dimensional stability, meaning they are less likely to warp or shrink. However, they lack the natural beauty of solid wood and require edge banding or other finishing treatments to conceal the exposed edges. When using engineered wood products, it's important to select a high-quality grade that is thick enough to support the weight of the bench.

Construction Techniques for Farm Table Benches

Successful farm table bench construction relies on accurate cutting, precise joinery, and careful assembly. A well-equipped workshop, along with a solid understanding of woodworking techniques, is essential for achieving a professional-quality result.

Cutting and Milling: Accurate cutting is crucial for ensuring that all the bench components fit together properly. A table saw is the most versatile tool for making straight cuts, while a miter saw is ideal for making angled cuts. A jointer and planer can be used to flatten and smooth the wood surfaces. If these tools are not available, lumber yards can often provide cutting and milling services. Always double-check measurements before cutting, and use a sharp blade to minimize splintering.

Joinery: The choice of joinery technique will influence the overall strength and aesthetic of the bench. Mortise and tenon joints, lap joints, and pocket screw joints are all suitable options. Mortise and tenon joints require precise cutting and fitting, but offer exceptional strength. Lap joints are easier to execute but still provide a strong connection. Pocket screw joints are the simplest to use, and are ideal for connecting aprons to the bench top and legs. When using pocket screws, be sure to use the correct screw length and set the drill bit to the proper depth.

Assembly: Before assembling the bench, dry-fit all the components to ensure that they fit together properly. This involves assembling the bench without glue or fasteners to check for any gaps or alignment issues. Once the dry fit is satisfactory, apply glue to the joints and clamp the components together. Use clamps that are appropriate for the size and shape of the bench. Allow the glue to dry completely before removing the clamps. After the glue has dried, reinforce the joints with screws or nails if desired. Ensure any fasteners are countersunk to allow for sanding and finishing.

Finishing and Protecting Your Farm Table Bench

The finishing process is crucial for enhancing the appearance and protecting the wood from moisture, scratches, and other damage. A variety of finishing options are available, each offering different levels of protection and aesthetic qualities.

Sanding: Sanding is an essential step in preparing the wood surface for finishing. Start with a coarse grit sandpaper (e.g., 80-grit) to remove any imperfections or scratches. Gradually work your way up to finer grits (e.g., 120-grit, then 220-grit) to create a smooth, even surface. Sand with the grain of the wood, and avoid applying too much pressure. After sanding, remove all dust with a vacuum cleaner or tack cloth.

Staining: Staining can enhance the natural color and grain of the wood. A wide range of stain colors are available, from light and natural tones to dark and rich hues. Apply the stain evenly with a brush, cloth, or foam applicator. Allow the stain to penetrate the wood for the recommended time, then wipe off any excess stain with a clean cloth. Allow the stain to dry completely before applying a topcoat.

Sealing and Topcoating: Sealing the wood protects it from moisture and prepares it for the topcoat. A variety of sealers are available, including polyurethane, varnish, and lacquer. Apply the sealer evenly with a brush or spray gun. Allow the sealer to dry completely before sanding lightly with a fine-grit sandpaper. After sanding, remove all dust and apply the topcoat. The topcoat provides a durable, protective finish that resists scratches and stains. Multiple coats of topcoat are recommended for maximum protection. A water-based polyurethane is a durable and low-VOC option for top coating. Mineral oil is another natural option but will require more frequent applications.

By carefully following these guidelines, builders can successfully create a beautiful and functional farm table bench that will enhance any dining or gathering space for years to come. The key is to plan carefully, select appropriate materials, and execute the construction with precision and attention to detail.

Beginner Farm Table Benches 2 Tools 20 In Lumber Ana White

Diy Farmhouse Table And Bench Honeybear Lane

Step By Diy Dining Bench Plans Wannabe Clutter Free Table Farmhouse

Diy Farmhouse Bench Love Grows Wild

Diy 40 Bench For The Dining Table Shanty 2 Chic

Diy Farmhouse Bench Love Grows Wild

Diy Farmhouse Table Bench Happiness Is Homemade

Diy Farmhouse Benches

Modern Farmhouse Dining Table Benches Erin Spain

How To Build A Farmhouse Bench For Under 20 In Supplies The Creative Mom

Related Posts