Folding Table Wood DIY: A Comprehensive Guide to Crafting Your Own Space-Saving Solution

Folding tables offer a practical solution for homes and workshops where space is a premium. They provide a temporary surface for dining, working, or hobbies, and can be easily stowed away when not in use. Constructing a folding table from wood is a rewarding DIY project that allows for customization and can result in a durable and aesthetically pleasing piece of furniture. This article provides a comprehensive guide to building a folding table from wood, covering design considerations, material selection, construction techniques, and finishing options.

Planning and Design Considerations

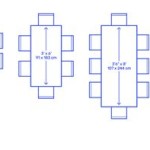

Before beginning any construction, thorough planning is essential. This involves determining the desired dimensions of the table, understanding the folding mechanism, and selecting appropriate materials. The size of the table should be dictated by its intended purpose. Consider the number of people it needs to accommodate for dining, the size of projects it needs to support for hobbies, or the space available for storage when folded.

The folding mechanism is a critical design element. Several options exist, each with its own advantages and disadvantages. A simple hinge system is the most straightforward, connecting the tabletop to a frame that folds down. Alternatively, drop-leaf tables utilize hinged leaves that can be raised or lowered to expand or reduce the tabletop area. A more complex mechanism might involve folding legs that lock into position when the table is open and release for folding.

Stability is paramount for any table, especially a folding one. The design must incorporate features that prevent wobbling or collapsing. This can be achieved through sturdy leg construction, robust hinges, and locking mechanisms that securely hold the legs in place when the table is in its open configuration. Cross braces between the legs can significantly enhance stability.

Finally, consider the aesthetic design. The style of the table should complement the existing decor of the room. Options range from rustic designs using reclaimed wood to modern designs featuring clean lines and minimalist hardware. The choice of wood species and finish will also significantly impact the overall appearance of the table.

Material Selection

The choice of wood is a crucial factor in determining the durability, appearance, and cost of the folding table. Several options are available, each with its own characteristics.

Hardwoods, such as maple, oak, and cherry, are known for their strength and durability. They are resistant to scratches and dents, making them suitable for tables that will see heavy use. Hardwoods also offer a wider range of grain patterns and colors, allowing for greater aesthetic flexibility. However, hardwoods are typically more expensive than softwoods.

Softwoods, such as pine and cedar, are more affordable and easier to work with. They are lighter in weight, which can be an advantage for a folding table that needs to be easily transported or stored. However, softwoods are more susceptible to damage and may require more frequent refinishing. Pine is a popular choice for rustic designs, while cedar offers natural resistance to insects and decay.

Plywood is a versatile material that can be used for the tabletop or other components of the table. It is stable and resistant to warping, making it a good choice for large surfaces. Plywood is available in a variety of thicknesses and finishes, including hardwood veneers that mimic the appearance of solid wood.

In addition to wood, other materials are needed for the construction of the folding table. These include hinges, screws, bolts, and wood glue. The hinges should be strong and durable, capable of withstanding repeated use. Choose screws and bolts that are appropriate for the type of wood being used and that will provide a secure connection. Wood glue is essential for bonding wood joints and should be applied carefully for maximum strength.

Construction Techniques

The construction of a folding table involves several key steps, including cutting the wood to size, assembling the frame, attaching the tabletop, and installing the folding mechanism.

Accurate cutting is essential for a well-constructed table. Use a saw, such as a circular saw or a miter saw, to cut the wood pieces to the dimensions specified in the design plan. Ensure that all cuts are square and that the pieces are the correct length. A measuring tape and square are indispensable tools for this step.

The frame provides the structural support for the table. It typically consists of four legs connected by rails. The legs can be simple straight pieces of wood or more elaborate designs with tapered legs or decorative details. The rails provide stability and support for the tabletop. Assemble the frame using wood glue and screws or bolts. Ensure that the joints are tight and secure.

The tabletop can be made from solid wood, plywood, or a combination of materials. Attach the tabletop to the frame using screws or bolts. Predrill pilot holes to prevent the wood from splitting. Ensure that the tabletop is centered on the frame and that it is securely fastened.

The folding mechanism is the heart of the table. Install the hinges or other components according to the manufacturer's instructions. Ensure that the mechanism operates smoothly and that the table folds and unfolds easily. Test the mechanism thoroughly to ensure that it is secure and reliable.

For a drop-leaf table, attach the leaves to the main tabletop using hinges. Install support brackets or legs that swing out to support the leaves when they are raised. Ensure that the brackets or legs lock into position securely.

If using a locking mechanism for the legs, carefully install the hardware according to the manufacturer's instructions. The locking mechanism should be easy to operate and should securely hold the legs in place when the table is open.

Sanding is a crucial step in preparing the wood for finishing. Use sandpaper of varying grits to smooth the surfaces of the wood and remove any imperfections. Start with a coarse grit sandpaper to remove any rough spots, then gradually move to finer grits to achieve a smooth finish. A sanding block or orbital sander can be used to make the process easier.

Finishing Options

The finish protects the wood from moisture, scratches, and stains, and also enhances its appearance. Several options are available, each with its own advantages and disadvantages.

Paint is a versatile option that allows for a wide range of colors and finishes. It is relatively easy to apply and can be used to create a variety of looks, from traditional to modern. Choose a paint that is specifically designed for wood and that is durable enough to withstand wear and tear. Apply several coats of paint, allowing each coat to dry completely before applying the next.

Stain enhances the natural grain and color of the wood. It is available in a variety of shades, from light to dark. Apply the stain evenly and allow it to penetrate the wood. Wipe off any excess stain with a clean cloth. After the stain has dried, apply a clear topcoat to protect the wood.

Varnish is a durable and protective finish that is available in a variety of sheens, from matte to gloss. It is resistant to water, scratches, and chemicals, making it a good choice for tables that will see heavy use. Apply several coats of varnish, allowing each coat to dry completely before applying the next. Sand lightly between coats to achieve a smooth finish.

Polyurethane is another durable and protective finish that is similar to varnish. It is available in both oil-based and water-based formulations. Polyurethane is resistant to water, scratches, and chemicals, and is easy to clean. Apply several coats of polyurethane, allowing each coat to dry completely before applying the next. Sand lightly between coats to achieve a smooth finish.

Oil finishes, such as linseed oil or tung oil, penetrate the wood and provide a natural look. They are easy to apply and maintain, but they are not as durable as other finishes. Apply several coats of oil, allowing each coat to penetrate the wood. Wipe off any excess oil with a clean cloth.

After applying the finish, allow it to dry completely before using the table. Follow the manufacturer's instructions for cleaning and maintenance to ensure that the finish lasts for many years.

Troubleshooting Common Problems

Even with careful planning and execution, problems can arise during the construction of a folding table. Understanding how to troubleshoot these problems can save time and frustration.

If the table wobbles, the legs may not be level. Check the legs with a level and adjust them as needed. If the legs are not adjustable, you may need to shim them with small pieces of wood or cardboard. Ensure that the frame is square and that all joints are tight.

If the folding mechanism is difficult to operate, lubricate the hinges with a silicone-based lubricant. Check to ensure that the mechanism is properly aligned and that there are no obstructions. Adjust the mechanism as needed to ensure that it operates smoothly.

If the wood splits when driving screws, predrill pilot holes that are slightly smaller than the diameter of the screws. Use screws that are appropriate for the type of wood being used. Avoid over-tightening the screws.

If the finish is uneven, sand the surface lightly and apply another coat of finish. Ensure that the wood is clean and dry before applying the finish. Use a brush or applicator that is appropriate for the type of finish being used.

If the wood warps, it may be necessary to replace it with a more stable material, such as plywood. Ensure that the wood is properly seasoned and that it is stored in a dry place. Apply a finish to protect the wood from moisture.

Free Woodworking Plans To Build A Fabulous Folding Table The Design Confidential

How To Make A Folding Table 20 Diy Plans

Woodsmith Multipurpose Folding Table Standard Plan Premium Drawings

Simple Diy Building A Folding Picnic Table From Pallet Wood

How To Make An Outdoor Folding Table Tutorial Pneumatic Addict

Free Woodworking Plans To Build A Fabulous Folding Table The Design Confidential

Diy Folding Table Ideas That You Can Build Easily Smart With Self Opening Legs

Folding Picnic Table Kreg Tool

Diy Folding Desk Jaime Costiglio

Solid Wood Folding Table With 4 Stools