Finding the Right Glass Table Top Protector Near You

Protecting glass tabletops is a paramount concern for homeowners, interior designers, and businesses alike. Glass surfaces, while aesthetically pleasing, are inherently vulnerable to scratches, chips, stains, and other forms of damage. A glass table top protector serves as a barrier, preserving the integrity and appearance of the glass while also extending its lifespan. The search for a "glass table top protector near me" is often initiated when individuals recognize the need to safeguard their investment or when they seek to restore the pristine condition of an existing glass surface.

The selection process for a glass table top protector necessitates careful consideration of several factors, including material type, thickness, size, shape, clarity, and cost. Locating a local provider simplifies the process of assessing these options firsthand, allowing for a more informed decision based on visual inspection and direct interaction with the product and vendor.

Understanding the Benefits of Local Sourcing

Opting for a local supplier of glass table top protectors offers several distinct advantages. These benefits extend beyond mere convenience and encompass factors such as personalized service, customizability, quicker turnaround times, and the opportunity to support local economies. Furthermore, the ability to physically examine samples can significantly influence the final purchase decision.

One significant benefit is the personalized service often provided by local businesses. These establishments tend to be more attuned to the specific needs of their immediate community, allowing them to offer tailored solutions and expert advice. This individualized attention can be particularly valuable when dealing with custom table shapes or unique protection requirements. Local suppliers are often more willing to work collaboratively with customers to ensure that the chosen protector perfectly fits the table and meets all performance expectations.

Another key advantage is the potential for customizability. Many local glass shops and specialty retailers offer custom cutting and shaping services, enabling customers to obtain protectors that precisely match the dimensions and contours of their tables. This is especially crucial for irregularly shaped tables, such as oval, round, or free-form designs, where standard-sized protectors may not provide adequate coverage. The ability to customize ensures a seamless and aesthetically pleasing integration of the protector with the existing table.

Quicker turnaround times are frequently associated with local sourcing. Unlike large national chains or online retailers that may have extended shipping times or limited inventory, local suppliers can often fulfill orders more rapidly. This is particularly advantageous for time-sensitive projects or when immediate protection is required to prevent further damage to a glass surface. Local production and distribution channels streamline the process, reducing delays and ensuring prompt delivery or installation.

Finally, supporting local businesses contributes to the economic vitality of the community. By choosing to purchase from a local provider, customers directly invest in the local economy, fostering job creation, and promoting sustainable economic growth. This sense of community engagement can be a significant factor in the decision-making process for many consumers.

Exploring Material Options and Their Properties

Glass table top protectors are available in a variety of materials, each possessing unique properties that influence their durability, clarity, heat resistance, and overall performance. The most common materials include tempered glass, acrylic (Plexiglas), polycarbonate (Lexan), and vinyl. Selecting the appropriate material depends on the specific application, budget, and aesthetic preferences.

Tempered glass is known for its exceptional strength and shatter-resistant properties. It is significantly stronger than standard annealed glass, making it highly resistant to impacts and scratches. In the event of breakage, tempered glass shatters into small, blunt fragments, reducing the risk of injury. Tempered glass protectors offer excellent clarity and heat resistance, making them suitable for dining tables and other surfaces where hot items may be placed.

Acrylic, also known as Plexiglas, is a lightweight and shatter-resistant alternative to glass. It offers excellent clarity and is available in a wide range of thicknesses. Acrylic is less prone to scratching than standard glass but can be susceptible to certain cleaning agents. Acrylic is a suitable option for coffee tables, desks, and other surfaces where weight is a concern. It is also generally more affordable than tempered glass.

Polycarbonate, marketed under the brand name Lexan, is an incredibly durable and impact-resistant thermoplastic. It is virtually unbreakable and can withstand extreme temperatures. Polycarbonate offers good clarity but may be more prone to scratching than tempered glass or acrylic. Polycarbonate protectors are ideal for heavy-duty applications, such as in environments with high traffic or where children are present.

Vinyl protectors are typically clear or frosted sheets that are placed on top of the glass surface. They are a cost-effective solution for preventing scratches and spills but offer limited protection against impacts and heat. Vinyl protectors are suitable for temporary protection or for surfaces that are not subject to heavy use. They are also easily replaceable.

When evaluating material options, it is essential to consider the trade-offs between durability, clarity, cost, and ease of maintenance. A local supplier can provide valuable guidance in selecting the material that best meets the specific requirements of the application.

Assessing Quality and Installation Considerations

The quality of a glass table top protector is directly related to its manufacturing process, the materials used, and the precision of the cutting and finishing. Poorly manufactured protectors may exhibit imperfections, such as bubbles, scratches, or uneven edges. Proper installation is also crucial to ensure the protector functions effectively and enhances the aesthetic appeal of the table.

When evaluating the quality of a glass table top protector, closely inspect the surface for any imperfections. Look for scratches, bubbles, or distortions in the material. Ensure that the edges are smooth and uniform, without any sharp or rough areas. The clarity of the protector should be consistent throughout, without any cloudiness or discoloration. If possible, request samples from different suppliers to compare the quality of their products side by side.

The thickness of the protector is another important factor to consider. A thicker protector will generally provide better protection against impacts and scratches. However, thicker protectors may also be more expensive and heavier. The appropriate thickness depends on the size and type of table, as well as the level of protection required. A local supplier can recommend the optimal thickness based on the specific application.

Proper installation is essential to ensure that the protector fits securely and does not slide or shift on the table surface. For glass and acrylic protectors, consider using clear silicone bumpers or adhesive pads to prevent slippage and provide a slight cushion. These bumpers should be strategically placed around the perimeter of the table to distribute the weight evenly. For vinyl protectors, ensure that the surface is clean and free of debris before applying the protector. Use a squeegee to remove any air bubbles and ensure a smooth, even surface.

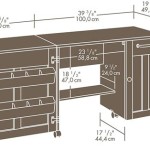

For custom-cut protectors, accurate measurements are critical. Carefully measure the table's length, width, and any curves or angles. Provide these measurements to the local supplier to ensure that the protector is cut to the precise dimensions. It is also advisable to request a template or drawing of the protector before it is cut to verify the accuracy of the measurements.

Finally, inquire about the supplier's warranty and return policy. A reputable supplier will stand behind their products and offer a warranty against defects in materials and workmanship. A flexible return policy provides added peace of mind in case the protector does not meet expectations or if any issues arise after installation.

Toughened Glass Table Top Protectors Made2measure

Painted Toughened Glass Table Top Protectors Made2measure

Glass Table Tops Furniture Shelves In Aiken Sc

Glass Table Tops Sydney Custom Made Valiant

Glass Table Tops All Purpose Glazing

Glass Table Tops The Pe A Division Of Builders Bonita Inc

Protecting Your Furniture With Glass Binswanger

Coloured Table Top Furniture Protectors In All Shapes Sizes

Should You Use Glass To Protect A Wood Table Cutesy Crafts

Clear Acrylic Round Tabletop Protectors Cover Wood Surface Protector To Keep Your Coffee End Table Dining Tables Bedside Protected

Related Posts