How to Make a Dining Room Table

Creating a dining room table is a challenging yet rewarding project for individuals with woodworking experience. It requires careful planning, precise execution, and a thorough understanding of woodworking techniques. This article details the step-by-step process of constructing a sturdy and aesthetically pleasing dining room table, covering aspects from material selection to finishing touches.

I. Planning and Design

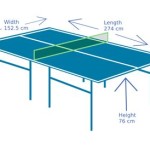

Before commencing any physical work, meticulous planning is essential. This stage involves determining the table's dimensions, style, and the type of wood to be used. The size of the dining room and the number of people the table will typically accommodate should dictate the table's length and width. Consider typical chair size when planning the table's width. The style, whether traditional, modern, rustic, or contemporary, will influence the design of the legs, apron, and tabletop. Detailed drawings or a CAD model can be beneficial in visualizing the final product and identifying potential problems early on. Planning accounts for material cost and necessary tools.

The design phase should also address structural considerations. The table must be sturdy enough to support the weight of dishes, food, and leaning individuals without wobbling or collapsing. This requires careful attention to the joinery used to connect the legs to the apron and the apron to the tabletop. The span of the tabletop also affects the design. Longer tables may require additional support in the form of a center stretcher or a thicker tabletop to prevent sagging.

Wood selection significantly impacts the table's appearance and durability. Hardwoods like maple, oak, cherry, and walnut are commonly chosen for their strength and resistance to dents and scratches. Softwoods like pine and fir are less expensive but more susceptible to damage. Consider the grain pattern and color of the wood when making your selection, as these will contribute to the overall aesthetic. If using multiple boards for the tabletop, plan the grain pattern to create a visually appealing surface. Sourcing lumber from a reputable supplier ensures the quality and consistency of the material.

II. Material Preparation and Cutting

Once the design is finalized and the materials are acquired, the next step is to prepare the wood. This involves milling the rough lumber to the desired dimensions, ensuring that all surfaces are flat, square, and parallel. A jointer is used to create a flat reference surface on one face of each board, followed by a planer to flatten the opposite face parallel to the first. A table saw is then used to rip the boards to the desired width, ensuring that the edges are perfectly straight and square. Wood of the right size creates the best building blocks for the table.

After milling, the individual components of the table—the legs, apron, and tabletop—are cut to their final dimensions. Precision is crucial at this stage, as any inaccuracies will accumulate and affect the overall fit and finish of the table. Use accurate measuring tools and sharp blades to ensure clean and precise cuts. Label each component clearly to avoid confusion during assembly.

For the tabletop, the individual boards must be joined together to create a single, wide panel. This is typically done using glue and clamps. The edges of the boards should be perfectly straight and square to ensure a tight, seamless joint. Apply glue evenly to both edges and clamp the boards together tightly, ensuring that they are aligned flush. Allow the glue to dry completely before removing the clamps. Once the glue is dry, the tabletop can be sanded smooth and flat.

III. Assembly and Joinery

The strength and stability of a dining room table depend heavily on the quality of the joinery used to connect the legs to the apron and the apron to the tabletop. Several types of joinery are commonly used in table construction, each with its own advantages and disadvantages.

Mortise and tenon joints are considered one of the strongest and most durable types of joinery. A mortise is a rectangular hole cut into one piece of wood (typically the apron), and a tenon is a corresponding projection cut onto the end of another piece of wood (typically the leg). The tenon is inserted into the mortise and secured with glue and sometimes a pin or wedge. Mortise and tenon joints provide excellent resistance to racking forces and are well-suited for tables that will be subjected to heavy use. This method of joinery ensures the stability of the overall structure.

Another common type of joinery is the dowel joint. Dowel joints use cylindrical wooden pegs (dowels) to align and reinforce the connection between two pieces of wood. Holes are drilled into both pieces of wood, and the dowels are inserted with glue. While not as strong as mortise and tenon joints, dowel joints are relatively easy to create and can provide adequate strength for many table designs. Proper alignment and consistent hole depth are essential for successful dowel joints.

Pocket hole joinery is a faster and simpler method that uses screws driven at an angle into pre-drilled holes. While not as aesthetically pleasing as other types of joinery, pocket hole joinery can be a good option for attaching the apron to the tabletop, as the screws are hidden from view. Pocket hole joinery is not recommended for connecting the legs to the apron, as it is not strong enough to withstand the stresses placed on those joints. The ease of use makes it attractive to some builders.

Regardless of the type of joinery used, it is important to ensure that all joints are tight, square, and properly aligned. Use clamps to hold the components in place while the glue dries. Inspect the joints carefully for any gaps or misalignments and make adjustments as needed. A well-executed joinery is the hallmark of a well-made table.

IV. Finishing and Protection

The final step in making a dining room table is to apply a finish that protects the wood and enhances its natural beauty. The choice of finish depends on the type of wood used, the desired aesthetic, and the level of durability required.

Oil finishes, such as linseed oil or tung oil, penetrate deep into the wood and provide a natural, matte appearance. Oil finishes are easy to apply and maintain but offer limited protection against water and scratches. They are best suited for tables that will not be subjected to heavy use or spills. Regular reapplication of oil is necessary to maintain the finish.

Varnish is a more durable finish that provides a hard, protective layer on the surface of the wood. Varnish is resistant to water, scratches, and stains and can be applied in multiple coats to achieve a desired level of sheen. Polyurethane varnish is a popular choice for dining room tables due to its durability and ease of application. Proper surface preparation is essential for a smooth, even varnish finish.

Lacquer is another durable finish that dries quickly and provides a high-gloss sheen. Lacquer is often used in commercial furniture production but can also be applied by hand with a brush or spray gun. Lacquer requires specialized equipment and ventilation, as it contains volatile organic compounds (VOCs). Consider the fumes when applying lacquer.

Before applying any finish, the table should be thoroughly sanded to remove any imperfections and create a smooth, even surface. Start with a coarse grit sandpaper (e.g., 120 grit) and gradually work up to a finer grit (e.g., 220 grit) for the final sanding. Remove all sanding dust with a tack cloth or vacuum cleaner before applying the finish. Apply the finish in thin, even coats, following the manufacturer's instructions. Allow each coat to dry completely before applying the next. Lightly sand between coats to remove any imperfections and create a smoother surface.

In addition to a protective finish, consider adding felt pads to the bottom of the legs to prevent scratching of the floor. These pads prevent the floor from potentially being damaged from the table's movement. Leveling the table is also a good idea. If your table has a wobble, adjust the feet on the legs to get it perfectly level.

Creating a dining room table is a project that demands precision, patience, and woodworking skill. This procedure details the planning, manufacturing, and finishing steps involved in constructing a table that is not only useful but also aesthetically pleasing. By following these procedures, one can construct a dining room table capable of serving your family for years to come.

How To Make A Diy Farmhouse Dining Room Table Restoration Hardware Knockoff Tips For

How To Make A Dining Room Table By Hand The Art Of Manliness

How To Make A Diy Farmhouse Dining Room Table Restoration Hardware Knockoff Tips For

How To Build A Dining Table H2obungalow

Diy Small Farmhouse Table Plans And Tutorial

Elsie S Diy Dining Room Table A Beautiful Mess

Diy Farmhouse Bench Love Grows Wild

Diy Oval Wood Beam Dining Table Grace Oaks Designs

Elsie S Diy Dining Room Table A Beautiful Mess

10 Diy Dining Table Ideas Build Your Own