How High Should A Cutting Table Be Placed In A Restaurant?

Determining the optimal height for a cutting table in a restaurant environment is crucial for ensuring efficiency, safety, and minimizing the risk of musculoskeletal disorders among kitchen staff. An improperly positioned cutting table can lead to back pain, fatigue, and decreased productivity. Multiple factors, including the height of the users, the type of tasks performed, and the overall kitchen layout, contribute to the ideal cutting table height. Understanding these considerations allows restaurant owners and managers to create a more ergonomic and productive workspace.

The placement of a cutting table refers not only to its vertical height but also its location within the kitchen. A well-placed cutting table should be easily accessible and integrated into the workflow, minimizing unnecessary movement and preventing bottlenecks. This article will delve into the factors influencing the ideal cutting table height in a restaurant setting, providing practical guidance for creating a safe and efficient work environment.

Understanding Ergonomics and Its Importance

Ergonomics is the science of designing workplaces and equipment to fit the people who use them. In a restaurant kitchen, where repetitive tasks are common, ergonomics plays a vital role in preventing work-related injuries and improving overall productivity. Applying ergonomic principles to the placement of a cutting table can significantly reduce the strain on a chef's body, allowing them to work more comfortably and efficiently.

Ignoring ergonomic considerations can lead to a range of musculoskeletal disorders, including carpal tunnel syndrome, tendonitis, and back pain. These conditions can result in decreased productivity, increased absenteeism, and higher healthcare costs. By prioritizing ergonomics in the kitchen design, restaurant owners can protect their employees' health and well-being, while also improving the restaurant's bottom line.

The key ergonomic principle to consider when determining cutting table height is to maintain a neutral posture. This means keeping the back straight, shoulders relaxed, and wrists in a neutral position. A cutting table that is too low will force the user to bend over, putting strain on the back. A cutting table that is too high will cause the user to raise their shoulders, leading to neck and shoulder pain. The ideal height will allow the user to work with their elbows bent at a 90-degree angle, minimizing strain on the body.

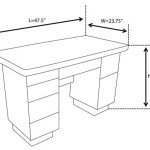

Beyond height, the depth and width of the cutting table also contribute to ergonomic design. A sufficient depth of the table allows for comfortable reach and placement of ingredients and equipment. The width should be adequate to accommodate the tasks being performed, preventing overcrowding and unnecessary reaching. A clear understanding of ergonomic principles is essential for creating a kitchen environment that supports the health and well-being of the staff.

Factors Influencing Optimal Cutting Table Height

Several factors must be considered when determining the optimal height for a cutting table in a restaurant. These factors range from the individual characteristics of the users to the specific tasks being performed on the table. A holistic approach, taking all these factors into account, is necessary to achieve the best ergonomic outcome.

The height of the primary users is the most crucial factor. Ideally, the cutting table height should be adjustable to accommodate different users. However, in many restaurants, this is not feasible. In such cases, the height should be based on the average height of the kitchen staff who will be using the table most frequently. A general guideline is to measure the distance from the floor to the user's bent elbow. The cutting table surface should be at or slightly below this height.

The type of tasks performed on the cutting table also plays a significant role. If the table is used primarily for fine cutting and intricate work, a slightly higher surface may be preferred to provide better visibility and control. Conversely, if the table is used for heavy-duty tasks such as chopping bones or cutting large quantities of vegetables, a slightly lower surface may be more suitable to allow for greater leverage and power. It is important to analyze the specific tasks that will be performed on the table to determine the optimal height.

The thickness of the cutting board should also be factored into the equation. A thicker cutting board will effectively raise the surface of the table, so the table height should be adjusted accordingly. Similarly, the type of footwear worn by the kitchen staff can affect their overall height and therefore the ideal table height. It is important to consider these seemingly minor details to ensure that the cutting table is truly ergonomic.

The surrounding environment and the overall flow of the kitchen impact the optimal placement and therefore the perception of height for a cutting table. A table that is easily accessible and well-lit will be more comfortable to use than one that is cramped or poorly lit. The distance between the cutting table and other workstations, such as the prep sink or the stove, should be minimized to reduce unnecessary movement and improve efficiency. Proper planning and layout are essential for creating a functional and ergonomic kitchen.

Practical Guidelines for Determining Cutting Table Height

While the theoretical considerations are important, practical guidelines are necessary to implement the optimal cutting table height in a real-world restaurant setting. These guidelines provide a step-by-step approach to assessing the needs of the kitchen staff and determining the appropriate table height.

The first step is to assess the needs of the kitchen staff. This involves gathering information about their height, the types of tasks they perform, and any existing musculoskeletal issues they may have. Conduct a survey or interview to collect this data. If possible, involve the kitchen staff in the decision-making process to ensure that their needs are met. Employee input can lead to greater satisfaction and compliance.

The next step is to measure the height of the primary users. Have each user stand upright with their arms bent at a 90-degree angle. Measure the distance from the floor to the bottom of their elbow. This measurement will serve as a starting point for determining the ideal cutting table height. Consider taking an average measurement if there are multiple users with varying heights.

The third step is to adjust the height based on the tasks being performed. If the table will be used primarily for fine cutting, add an inch or two to the measurement. If the table will be used for heavy-duty tasks, subtract an inch or two. This adjustment will help to optimize the table height for the specific tasks being performed. It's important to consider the balance between visibility, control, and leverage.

The fourth step is to consider the cutting board thickness. If a thick cutting board will be used, subtract its thickness from the target table height. This will ensure that the final surface height is appropriate for the users. Remember that a thicker cutting board can significantly alter the effective table height. Finally, if adjustable height tables are an option given the budget, this allows for all users and tasks to find the optimal height for each.

The final step is to test the table height in a real-world setting. Have the kitchen staff use the table for a few days and provide feedback. Observe their posture and movements to identify any potential ergonomic issues. Make any necessary adjustments based on the feedback and observations. This iterative process can help to fine-tune the table height and ensure that it meets the needs of the kitchen staff.

In addition to the height of the cutting table, the surface material is also important. Stainless steel is a common choice for its durability and ease of cleaning. However, it can be hard on knives and can cause fatigue over long periods. Consider using a cutting board made of wood or a softer material to reduce strain on the knives and the user's wrists. Furthermore, ensure that the cutting table is stable and does not wobble. A wobbly table can be dangerous and can contribute to musculoskeletal disorders.

Proper lighting is critical to optimize cutting board placement. Ensure that the area around the cutting table is well-lit, as poor lighting can cause eye strain and fatigue. Use task lighting to focus on the cutting surface and improve visibility. Position the lighting to minimize glare and shadows. Good lighting improves safety and efficiency.

By following these practical guidelines, restaurant owners and managers can create a kitchen environment that is both safe and efficient. Prioritizing ergonomics in the kitchen design can lead to improved employee health, increased productivity, and a better overall work environment.

Manual Vegetable Cutting Table For Restaurant Capacity 100 Kg At Rs 20000 Piece In Mumbai

Industrial Restaurant Kitchen Workbench Whole Stainless Steel Cutting Table With Bottom Shelf As Fast Food Equipment China Made In Com

How To Set A Table Place Setting Guide Robert Welch Designs Ltd

Stainless Steel Commercial Work Table For Kitchen And Restaurant Use As Cutting With Storage Shelf China Workbench Made In Com

Industrial Restaurant Kitchen Workbench Whole Stainless Steel Cutting Table With Bottom Shelf As Fast Food Equipment China Made In Com

5 Types Of Restaurant Table Setting Every Owner Must Know

White Big Round Solid Surface Dining Table Set For Restaurant China Made In Com

How To Choose The Right Dining Table For Your Home New York Times

Stainless Steel Commercial Work Table For Kitchen And Restaurant Use As Cutting With Storage Shelf China Workbench Made In Com

Types Of Cutting Boards Materials Sizes Colors Shapes