How to Build a Shuffleboard Table: A Comprehensive Guide

Constructing a shuffleboard table can be a rewarding woodworking project, providing a centerpiece for entertainment and friendly competition. This article provides a detailed guide to build a high-quality shuffleboard table. While the project requires patience, specific tools, and a commitment to precision, the result is a durable and enjoyable addition to any game room or recreation space.

Before embarking on this project, it is crucial to consider the size of the table. Shuffleboard tables typically range in length from 9 to 22 feet. The dimensions should be chosen based on the available space. A common and manageable size for a home table is 12 feet long and 20 inches wide for the playing surface. This guide will focus on constructing a table of approximately this size, but the principles can be adapted for larger or smaller dimensions. Careful planning considering where the table will reside is important before starting any cutting of wood.

Acquiring the necessary materials and tools is a prerequisite. The primary material is hardwood for the playing surface and frame. Maple is a common choice for the playing surface due to its density, durability, and smooth grain. Poplar or birch can be used for the frame and base. Ensure the wood is kiln-dried to minimize warping. Other necessary materials include epoxy resin for coating the playing surface, felt for the gutters, and hardware such as screws, bolts, and leveling feet. Specific tools needed include a table saw, planer, jointer (optional but highly recommended), router, sander, drill, measuring tape, level, and clamps. Safety equipment such as safety glasses, dust mask, and hearing protection are also essential.

Key Point 1: Preparing the Playing Surface

The playing surface is arguably the most critical component of the shuffleboard table. The goal is to create a perfectly flat, smooth, and level surface for optimal gameplay. This requires careful preparation and precise woodworking techniques.

Begin by selecting the maple boards for the playing surface. The number of boards will depend on the desired width of the table and the width of the individual boards. Ideally, wider boards are preferable as they minimize the number of seams. Inspect each board for any defects, such as knots or excessive grain irregularities. These defects can affect the flatness and smoothness of the final surface.

The next step involves jointing and planing the boards. Jointing creates a perfectly straight edge on each board, while planing ensures a consistent thickness and smooth surface. If a jointer is available, it should be used to create the initial straight edge. If not, a table saw can be used, but requires careful attention to alignment. Each board should then be planed to the desired thickness, typically between 1.5 and 2 inches. Consistency in thickness is crucial for achieving a flat playing surface.

Once the boards are jointed and planed, they can be glued together to form the complete playing surface. Apply a generous amount of wood glue to the edges of each board and clamp them together tightly. Ensure the boards are aligned perfectly, using clamps to apply pressure both vertically and horizontally. Allow the glue to dry completely, typically for at least 24 hours. It is imperative that the glue lines are as tight as possible. Consider using a high-quality wood glue designed for edge-to-edge laminations.

After the glue has dried, remove the clamps and inspect the playing surface. Use a hand plane or sander to remove any excess glue and level any minor discrepancies between the boards. The playing surface should now be a single, solid piece of wood. Use a long straightedge to verify that the surface is flat and level in all directions. Any significant deviations will need to be addressed before proceeding.

Sanding the playing surface is the final step in preparation. Start with a coarse grit sandpaper (e.g., 80 grit) and gradually work your way up to finer grits (e.g., 120, 180, 220 grit). Ensure the entire surface is evenly sanded, paying particular attention to the seams between the boards. The goal is to create a perfectly smooth and uniform surface that is ready for the epoxy coating. Before applying the epoxy, thoroughly clean the surface to remove any dust or debris. Compressed air and a tack cloth are effective for this purpose.

Key Point 2: Constructing the Frame and Base

The frame and base provide structural support for the playing surface. The frame surrounds the playing surface and provides a rigid enclosure, while the base supports the entire table and allows for leveling adjustments. The frame and base should be constructed from durable materials such as poplar or birch.

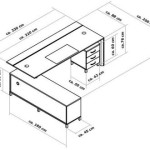

Begin by measuring the dimensions of the playing surface. The frame should be slightly larger than the playing surface to allow for a small gap around the perimeter. This gap is typically ¼ to ½ inch and allows for expansion and contraction of the wood. Cut the frame pieces to the appropriate length using a table saw. The frame typically consists of four pieces: two long pieces for the sides and two shorter pieces for the ends.

The frame pieces can be joined together using a variety of methods, such as miter joints, butt joints, or mortise and tenon joints. Miter joints provide a clean and professional look, but require precise cutting. Butt joints are simpler to construct but may not be as strong. Mortise and tenon joints are the strongest but require more advanced woodworking skills. Regardless of the chosen method, ensure the joints are strong and secure.

Glue and screw the frame pieces together. Use clamps to apply pressure while the glue dries. After the glue has dried, reinforce the joints with screws. The screws should be countersunk to prevent them from interfering with the playing surface. The frame should now be a rigid and rectangular enclosure. Check for squareness using a framing square and make any necessary adjustments.

The base can be constructed from a variety of designs, depending on the desired aesthetics and stability. A simple base can be made from four legs connected by cross braces. A more elaborate base can include a cabinet or other decorative elements. The height of the base should be chosen based on the desired playing height of the table, typically around 30 to 32 inches.

Cut the base pieces to the appropriate length using a table saw. Assemble the base using screws and glue. Ensure the base is level and stable. Reinforce the joints with metal brackets or additional wood supports. Leveling feet can be added to the bottom of the base to allow for fine-tuning of the table's level on uneven surfaces. Attach the frame to the base using screws or bolts. Ensure the frame is securely attached to the base and that the playing surface is level.

Key Point 3: Applying the Epoxy Coating and Finishing Touches

The epoxy coating provides a durable, glossy, and smooth surface for the shuffleboard pucks to glide on. The application of epoxy requires careful preparation and attention to detail.

Select a high-quality epoxy resin specifically designed for coating shuffleboard tables. Follow the manufacturer's instructions for mixing the epoxy resin and hardener. The epoxy should be mixed thoroughly to ensure proper curing. Before applying the epoxy, ensure the playing surface is clean and free of any dust or debris. A tack cloth is recommended for this purpose.

Pour the epoxy onto the playing surface. Use a squeegee or spreader to evenly distribute the epoxy across the entire surface. The epoxy should be applied in a thin, uniform layer. Work quickly to prevent the epoxy from setting before it is fully spread. Use a heat gun or torch to remove any air bubbles from the epoxy. The heat will cause the bubbles to rise to the surface and pop.

Allow the epoxy to cure completely, typically for at least 24 to 72 hours, depending on the manufacturer's instructions. The epoxy should be hard and smooth to the touch. After the epoxy has cured, inspect the surface for any imperfections, such as unevenness or air bubbles. If necessary, sand the imperfections using fine-grit sandpaper and apply another coat of epoxy.

Once the epoxy coating is complete, install the gutters around the perimeter of the playing surface. The gutters catch the shuffleboard pucks when they fall off the table. The gutters can be made from wood or metal. Line the gutters with felt to reduce noise and protect the pucks.

Add the scoring lines to the playing surface. The scoring lines mark the different scoring zones on the table. The scoring lines can be painted or applied with decals. Ensure the scoring lines are accurately placed according to the official shuffleboard rules. Apply a clear coat of finish to the frame and base to protect the wood and enhance its appearance. The finish can be varnish, polyurethane, or lacquer. Allow the finish to dry completely before using the table.

Finally, inspect the completed shuffleboard table for any remaining imperfections or adjustments. The table should be level, stable, and have a smooth, consistent playing surface. Ensure the scoring lines are accurate and the gutters are properly installed. The construction of a shuffleboard table is a significant undertaking. The completed table provides a unique and enjoyable form of recreation.

Shuffleboard Table Rogue Engineer

How To Build A Shuffleboard Table Free Plans

How To Make A Shuffleboard Table With S Wikihow

Shuffleboard Table Rogue Engineer

How To Make A Shuffleboard Table With S Wikihow

How To Make A Shuffleboard Table With S Wikihow

Shuffleboard Table Rogue Engineer

How To Build A Shuffleboard Table Planos De Móveis Jogos Jardim Ideias Legais

How To Make A Shuffleboard Table With S Wikihow

How To Set Up And Install A Shuffleboard Table