How To Build A Simple Bar Table

Building a bar table can be a rewarding project, offering a customized addition to a living space or entertainment area. This article provides a detailed guide on how to construct a simple bar table, suitable for beginners with basic woodworking skills. Careful planning, accurate measurements, and diligent execution are crucial for achieving a stable and aesthetically pleasing result. The instructions outlined below will cover the necessary materials, tools, and step-by-step procedures. Attention to detail in each stage of the process is paramount for a durable and functional bar table.

The construction of a bar table involves several key stages, starting from material selection and design planning to assembly and finishing. The choice of materials directly influences the table's durability, appearance, and overall cost. Pine and other softwoods are suitable for budget-conscious projects and offer ease of workability. Hardwoods like oak or maple present greater durability and a more refined aesthetic but require more advanced woodworking skills and tools. The design can be adapted to personal preferences and space constraints, encompassing variations in height, shape, and storage options. This article focuses on a straightforward design, adaptable to individual customizations.

Planning and Material Acquisition

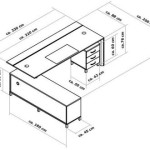

The initial phase involves meticulous planning and acquisition of the necessary materials. A detailed plan reduces errors and optimizes material usage. Begin by determining the desired dimensions of the bar table. Standard bar table heights generally range from 40 to 42 inches, but personal preference and seating arrangements should influence this decision. The width and depth of the tabletop depend on the intended use and available space. A comfortable depth for a bar top is typically between 20 and 24 inches, while the width can be adjusted to accommodate the desired number of users. Once the dimensions are finalized, a materials list can be compiled.

The following materials are typically required for a simple bar table: *

Tabletop material:

A pre-made tabletop can be purchased, or lumber can be used to create one. For this example, lumber is considered. Select lumber of the desired type and thickness. A minimum thickness of 1 inch is recommended for stability. The quantity will depend on the desired dimensions of the tabletop. *Legs:

Pre-made table legs can be purchased from hardware stores or online retailers. Alternatively, legs can be constructed from lumber. If constructing legs, select lumber with appropriate dimensions to ensure adequate support. Four legs are needed for a standard rectangular or square bar table. If a different shapes are desired, the amount of legs should be considered at planning. *Aprons (optional):

Aprons are horizontal pieces of lumber that connect the legs and provide additional support for the tabletop. They are typically made from the same type of lumber as the legs. The length of the aprons will depend on the dimensions of the table and the placement of the legs. *Fasteners:

Wood screws of varying lengths are required to assemble the different components. Select screws that are appropriate for the thickness of the lumber being used. Wood glue is also recommended for enhanced structural integrity. *Finishing materials:

Sandpaper of various grits (e.g., 80, 120, 220), wood stain (optional), and a clear coat finish (e.g., polyurethane) are needed to protect and enhance the appearance of the bar table.In addition to materials, the following tools are essential for constructing the bar table: *

Measuring tape:

For accurate measurements. *Pencil:

For marking cut lines and screw locations. *Saw:

A circular saw or hand saw can be used to cut the lumber. A miter saw is helpful for making precise angle cuts. *Drill:

For drilling pilot holes and driving screws. *Screwdriver:

For manually driving screws. *Clamps:

To hold pieces together while glue dries. *Sander:

An orbital sander expedites the sanding process, but sandpaper and a sanding block can also be used. *Safety glasses:

To protect eyes from dust and debris. *Work gloves:

To protect hands.Assembly Process

Following material acquisition, the assembly process can commence. The initial step involves preparing the lumber. If using rough-sawn lumber, it will need to be planed and jointed to achieve smooth, square surfaces. This process ensures accurate dimensions and enhances the aesthetic appeal of the finished product.

If constructing the tabletop from multiple boards, the boards must be joined together. Apply wood glue to the edges of the boards and clamp them together tightly. Allow the glue to dry completely (usually 24 hours) before removing the clamps. Once the glue is dry, sand the tabletop to create a smooth, even surface. Start with a coarse grit sandpaper (e.g., 80 grit) and gradually move to finer grits (e.g., 120, 220 grit).

Next, prepare the legs. If using pre-made legs, ensure they are the correct height and have mounting hardware. If constructing legs from lumber, cut the lumber to the desired length. Ensure that all four legs are the same length to prevent the table from wobbling. If using aprons, cut them to the appropriate length. The length of the aprons will depend on the dimensions of the table and the placement of the legs.

Attach the legs to the tabletop. If using aprons, attach the aprons to the legs first. Apply wood glue to the ends of the aprons and clamp them to the legs. Secure with wood screws. Ensure that the aprons are square to the legs. When the glue is cured, the apron and the legs will create a frame. Then attach the aprons with the legs to the tabletop. Center the frame over the tabletop and secure with wood screws. Drill pilot holes through the aprons and into the tabletop to prevent the wood from splitting. Apply wood glue to the aprons before screwing them to the tabletop for added strength. If not using aprons, position the legs at the desired locations on the underside of the tabletop. Ensure the legs are evenly spaced and properly aligned. Attach the legs using wood screws. Countersink the screws to create a flush surface.

After completing the assembly, inspect the bar table for any imperfections or structural weaknesses. Tighten any loose screws and reinforce any weak joints with additional screws or glue. Address any uneven surfaces or sharp edges with sandpaper.

Finishing and Customization

The final stage involves finishing and customization. Sand the entire bar table to create a smooth, even surface. Start with a medium-grit sandpaper (e.g., 120 grit) and gradually move to finer grits (e.g., 220 grit). Remove any sanding dust with a tack cloth or vacuum cleaner.

If desired, apply a wood stain to the bar table. Follow the manufacturer's instructions for application and drying time. A stain enhances the wood grain and adds color to the table. Multiple coats can be applied to achieve the desired intensity. Wiping the table with a tac cloth between coats ensures a smooth and uniform finish.

Apply a clear coat finish to protect the bar table from scratches, stains, and moisture. Polyurethane is a popular choice due to its durability and ease of application. Apply several thin coats of polyurethane, allowing each coat to dry completely before applying the next. Sand lightly between coats with fine-grit sandpaper (e.g., 320 grit) to create a smooth surface. Avoid thick coats of finish as it could ruin the appearance of the product.

Customization options are abundant. Install a foot rail around the base of the table for added comfort. Add storage shelves or cabinets to the underside of the tabletop for storing bar accessories. Incorporate decorative elements such as metal accents or carved details. Personalize the bar table with custom paint colors or stencils. The finished bar table should be functional, aesthetically pleasing, and well-suited to its intended use. To increase its durability it's worth to consider adding additional layer of protective coat.

Consider the environment in which the table will be placed. A bar table intended for outdoor use requires a more durable finish to withstand the elements. Marine-grade varnishes or exterior-grade polyurethanes are recommended for outdoor applications. Regularly inspect the bar table for signs of wear and tear. Tighten any loose screws, repair any damaged finish, and address any structural issues promptly to prolong the life of the table. With proper care and maintenance, the bar table will provide years of enjoyment.

How To Make Your Own Outdoor Bar Table In Honor Of Design

Diy Pub Table

How To Build A 2x4 Outdoor Bar Table The Diy Dreamer

Diy Pub Table A Step By Tutorial Bar Furniture

Diy Pub Table

Diy 25 Pub Table Kitchen Island Project Fast And Easy Great For All Skill Levels

How To Build A 2x4 Outdoor Bar Table Diy

Outdoor Bar Table Ana White

Farmhouse Coffee Bar Table 6 Steps To Build It Free Building Plans

Build A Simple Bar Shelf For Extra Seating