How To Make A Shuffleboard Table Top

Constructing a shuffleboard table top is a challenging yet rewarding project for woodworking enthusiasts. It requires precision, patience, and a solid understanding of woodworking techniques. The result is a durable and aesthetically pleasing playing surface that can provide years of entertainment. This article details the process, from material selection to finishing, to guide individuals through the creation of a regulation or custom-sized shuffleboard table top.

Material Selection and Preparation

The first crucial step involves selecting the appropriate wood for the table top. Hardwoods are generally preferred due to their durability and ability to withstand the impact of the pucks. Popular choices include maple, birch, and oak. Maple is particularly favored for its smooth grain and resistance to wear and tear. The thickness of the wood is also a critical factor. A minimum thickness of 1.5 inches is recommended to prevent warping and provide a stable playing surface. Wider tables may require even thicker wood.

Once the wood is selected, it must be properly acclimatized to the environment where the table will reside. This process, known as seasoning, involves storing the wood in a controlled environment with consistent temperature and humidity for several weeks. This allows the wood to adjust to the moisture levels and minimizes the risk of warping or cracking after construction. Failure to properly acclimatize the wood can lead to significant problems later on.

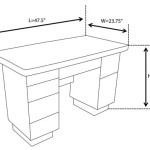

After acclimatization, the wood planks need to be milled to the correct dimensions. This involves using a jointer to create a perfectly flat and square surface on one side of each plank. Then, a planer is used to achieve the desired thickness and create a parallel surface on the opposite side. Finally, a table saw is used to rip the planks to the correct width. Precision in this step is essential to ensure a smooth and consistent playing surface.

Once the planks are milled, they need to be joined together to form the table top surface. There are several methods for joining wood, including using glue joints, tongue-and-groove joints, or biscuits. For a shuffleboard table, a strong and seamless joint is crucial. A glue joint is typically the best option, using a high-quality wood glue specifically designed for hardwoods. Clamps are used to apply even pressure across the entire joint while the glue dries. It is essential to ensure that the planks are perfectly aligned before applying the clamps to avoid any unevenness in the final surface.

After the glue has dried completely, the clamps are removed, and the joined planks are ready for sanding. This process involves using progressively finer grits of sandpaper to achieve a smooth and even surface. Starting with a coarse grit, such as 80-grit, removes any imperfections and prepares the surface for finer sanding. Subsequent passes with 120-grit, 180-grit, and finally 220-grit sandpaper will result in a glass-like surface. It is important to sand in the direction of the grain to avoid creating scratches.

Creating the Regulation Shuffleboard Surface Characteristics

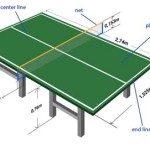

A key characteristic of a regulation shuffleboard table is the slight concave curve along its length, often referred to as the "dish." This subtle curve assists with play, especially for those playing professionally. To achieve this, specialized woodworking techniques must be employed. The most common approach involves using a large radius dish plane or a custom-built jig for a router. The dish is typically only a few millimeters deep at its deepest point.

The creation of the dish requires careful attention to detail. The curve should be consistent and symmetrical along the entire length of the table. This step can significantly impact the playability of the table, so it is crucial to take the time to ensure that it is done correctly. Frequent checks with a straightedge and feeler gauges are recommended to monitor the progress and ensure that the curve is uniform.

Another important aspect of a shuffleboard table is the presence of scoring zones at both ends of the table. These zones are typically marked with painted lines or inlaid wood. The dimensions of these zones are specified in the official shuffleboard regulations. It is crucial to accurately measure and mark these zones to ensure fair play. If paint is used, it should be a durable and fade-resistant paint specifically designed for wood. If inlaid wood is used, it should be a contrasting color to the main table surface for easy visibility.

The surface of the shuffleboard table must also be perfectly level. This can be achieved by using a long level and shims to adjust the height of the table legs. It is important to check the level in multiple directions to ensure that the table is perfectly flat. A level surface is essential for accurate and consistent play.

In addition to the dish and level surface, the table should be free of any imperfections that could interfere with the movement of the pucks. This includes bumps, dents, and scratches. Any imperfections should be carefully repaired before applying the final finish.

Finishing and Sealing the Table Top

The final step involves applying a durable finish to protect the wood and create a smooth playing surface. Polyurethane is a popular choice for shuffleboard tables due to its durability and resistance to scratches and moisture. Multiple coats of polyurethane are typically applied, with sanding between each coat to ensure a smooth and even finish. A minimum of three coats is recommended.

Before applying the finish, the table should be thoroughly cleaned to remove any dust or debris. A tack cloth is an effective tool for removing fine particles. The finish should be applied in a thin and even coat, following the manufacturer's instructions. It is important to allow each coat to dry completely before applying the next coat.

Between coats of polyurethane, the surface should be lightly sanded with a fine-grit sandpaper, such as 320-grit. This will help to remove any imperfections and create a smooth surface for the next coat. After sanding, the surface should be thoroughly cleaned to remove any sanding dust.

The final coat of polyurethane should be allowed to dry for at least 24 hours before using the table. This will allow the finish to fully cure and harden. Once the finish is dry, the table can be polished with a soft cloth to enhance the shine. Some individuals will use a very fine steel wool to buff the final coat of polyurethane, but this requires extreme care.

Applying a sealant designed specifically for shuffleboard tables is highly recommended. These sealants are typically made of silicone and are designed to fill any small imperfections in the surface and create a smooth and frictionless playing surface. The sealant should be applied evenly across the entire surface of the table, following the manufacturer's instructions.

Maintaining the shuffleboard table top is essential to ensure its longevity and optimal performance. Regular cleaning with a soft cloth and a mild cleaner is recommended. Avoid using harsh chemicals or abrasive cleaners, as these can damage the finish. A shuffleboard table is a fine piece of woodworking that can provide a lifetime of enjoyment if properly cared for.

How To Build A Shuffleboard Table Free Plans

:max_bytes(150000):strip_icc()/43944-a1a854e4b01548fcb267e17b10ceaef1.jpg?strip=all)

Tabletop Shuffleboard Woodworking Plan

Epic 14ft Shuffle Board Build

Shuffleboard Table Rogue Engineer

Shuffleboard Table Rogue Engineer

How To Make A Shuffleboard Table With S Wikihow

How To Make A Shuffleboard Table With S Wikihow

Shuffleboard Table Rogue Engineer

5 Day Build No Thought We Could Do It

Shuffleboard Table Rogue Engineer