How To Turn A Tree Trunk Into A Table

Creating a table from a tree trunk involves several steps, from selecting the right piece of wood to the final finishing touches. This guide provides a comprehensive overview of the process, equipping readers with the knowledge to transform a raw piece of nature into a functional and aesthetically pleasing piece of furniture.

1. Selecting and Preparing the Trunk

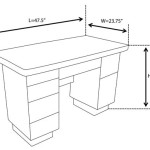

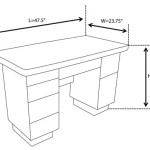

The first step is choosing a suitable tree trunk. Consider the desired size and shape of the finished table. Hardwoods like oak, maple, or walnut are generally preferred for their durability and resistance to wear and tear. However, softer woods can be used if properly sealed and protected. The trunk should be free from significant rot or insect damage. Inspect the wood carefully for any signs of decay, such as soft spots, discoloration, or insect holes. Once selected, the trunk needs to be cut to the desired length. A chainsaw is the most efficient tool for this, but ensure appropriate safety precautions are taken. It's essential to create a level surface on both ends of the trunk. This can be achieved using a chainsaw mill, a large flat saw, or by carefully working with a regular chainsaw.

After cutting the trunk, the bark needs to be removed. A drawknife, bark spud, or even a chisel can be used for this process. Work carefully to avoid gouging the wood beneath. Removing the bark helps prevent insect infestations and allows for better assessment of the wood's condition. Once the bark is removed, the trunk should be allowed to dry. This is crucial to prevent cracking and warping of the finished table. The drying process, known as seasoning, can take several months, depending on the wood type and climate. Air drying is a slow but effective method. The trunk should be stored in a dry, well-ventilated area, off the ground, and protected from direct sunlight. Alternatively, kiln drying can significantly reduce the drying time, but may be more expensive.

2. Leveling and Finishing the Surface

Once the wood is adequately seasoned, the top surface needs to be leveled. A power planer is the most efficient tool for this task, but hand planing can also be used for smaller trunks. The goal is to create a smooth, even surface. Any remaining imperfections can be addressed with sanding. Start with a coarser grit sandpaper and gradually move to finer grits for a polished finish. A random orbital sander can make this process quicker and more efficient. The sides of the trunk can also be sanded and shaped at this stage, depending on the desired aesthetic.

After sanding, decisions must be made about the table's base. Several options exist. Metal legs offer a modern, industrial look and are readily available. Creating a base from another piece of wood, perhaps a contrasting species, adds a rustic, natural appeal. Another option is to create a pedestal base from the same trunk if enough material is available. Attaching the base requires careful planning and execution. Metal legs can be bolted directly to the underside of the table top. Wooden bases require more complex joinery techniques, such as mortise and tenon or dowel joints. Ensuring a secure and stable connection is critical.

3. Sealing and Protecting the Table

The final step involves sealing and protecting the wood. This helps enhance the table's natural beauty and protects it from moisture, stains, and scratches. Numerous finishes are available, each offering different levels of protection and sheen. A clear polyurethane finish is a popular choice, providing excellent durability and water resistance. Oil-based finishes enhance the wood's natural grain and offer a warm, rich look. Wax finishes offer a more natural look and feel but require more frequent reapplication.

Before applying the finish, it's often beneficial to apply a wood conditioner. This helps ensure even absorption of the finish, especially on porous woods. Apply the finish according to the manufacturer's instructions, typically in multiple thin coats, allowing sufficient drying time between each coat. Light sanding between coats can further enhance the smoothness of the finish. Once the final coat has dried, the table is ready to be used and enjoyed, showcasing the unique character of the original tree trunk.

Creating a table from a tree trunk can be a rewarding endeavor. With careful planning, the right tools, and patience, a unique and beautiful piece of furniture can be crafted that will last for generations.

How To Diy Stump Table 17 Apart

How To Make A Tree Stump Table Diy Trunk

Diy Natural Tree Stump Side Table Justinecelina

The Tree Is Coming Down So Make Most Of It

How To Diy Stump Table 17 Apart

Make A Tree Stump Side Table Simply Designing With Ashley

Turn Old Tree Stump Into Unique Coffee Table Diy

Diy Tree Stump Side Tables A Beautiful Mess

How To Make A Table From Tree Slice

Diy Log Coffee Table