Metal Base For Table: A Comprehensive Guide

The metal base for a table is a critical component that provides stability, support, and influences the overall aesthetic. These bases are utilized across a wide spectrum of table types, from dining tables and coffee tables to conference and workstation surfaces. The selection of a suitable metal base necessitates careful consideration of numerous factors, including the intended application, load-bearing requirements, design style, and environmental conditions. A thorough understanding of the available options, materials, and construction methods is essential for making an informed decision.

Metal bases offer several advantages over bases constructed from other materials like wood or plastic. Their inherent strength and durability allow them to support heavier table tops and withstand significant wear and tear. Metal is also less susceptible to warping, cracking, or insect infestation, making it a long-lasting and reliable choice. Furthermore, the versatility of metal allows for a wide range of designs, from sleek and modern to more ornate and traditional styles. The finish options, including powder coating, plating, and polishing, further enhance the aesthetic possibilities.

Understanding the Different Types of Metal Table Bases

Metal table bases are available in various configurations, each suited to specific applications and design preferences. Understanding these different types is crucial for selecting the most appropriate base for a given table project.

Pedestal Bases: These bases consist of a single central support column, typically mounted on a weighted base. Pedestal bases offer unobstructed legroom and are often favored for round or square tables. The design of the pedestal can vary significantly, from simple cylindrical shapes to more elaborate designs with multiple tiers or decorative elements. The stability of a pedestal base depends largely on the size and weight of the base, as well as the diameter of the table top it supports. Consideration should be given to the distribution of weight on the table top to prevent tipping, especially with larger or irregularly shaped surfaces.

Four-Legged Bases: This is perhaps the most common type of table base, providing a stable and balanced platform for various table shapes and sizes. The legs can be straight, tapered, splayed, or curved, allowing for a wide range of design aesthetics. The spacing and angle of the legs are crucial for stability, particularly for larger tables or those subject to heavy loads. Four-legged bases can be constructed from solid metal bars, tubing, or fabricated from multiple pieces welded together. The method of attachment to the table top also plays a crucial role in the overall strength and stability of the table.

Trestle Bases: Trestle bases are characterized by two or more vertical supports connected by a horizontal beam or stretcher. This design offers a traditional and often rustic aesthetic. Trestle bases are frequently used for dining tables, conference tables, and workbenches. The strength and stability of a trestle base depend on the size and thickness of the supporting members, as well as the quality of the joinery or welding between the components. The stretcher provides added rigidity and prevents the legs from splaying outward under load. The placement of the trestle supports should be carefully considered to ensure adequate legroom and prevent interference with chairs or other furniture.

Spider Bases: Often used for restaurant tables or smaller cafe tables, spider bases feature a central column branching out into several feet. This design optimizes stability while minimizing obstruction around the table's perimeter. The "legs" of the spider base are typically flat metal bars that provide a wide footprint for support. Spider bases are typically paired with round or square table tops and are available in various sizes and heights to accommodate different applications.

Adjustable Height Bases: These bases incorporate a mechanism that allows the table height to be adjusted, providing versatility for use in various settings. Adjustable height bases are commonly employed in offices, workshops, and healthcare facilities. The adjustment mechanism can be manual, using a crank or lever, or electric, using a motor. The weight capacity and stability of adjustable height bases are critical considerations, particularly when the table is fully extended. The quality of the adjustment mechanism and the robustness of the supporting structure are crucial for ensuring smooth and reliable operation.

Common Metals Used in Table Base Construction

The choice of metal significantly impacts the strength, durability, appearance, and cost of the table base. Different metals offer varying properties and are suitable for different applications and design styles.

Steel: Steel is a widely used material for table bases due to its high strength, durability, and relatively low cost. Steel bases can be fabricated in various shapes and sizes, making them suitable for a wide range of table designs. Steel is susceptible to rust and corrosion, so it is typically finished with a protective coating, such as powder coating or plating. Stainless steel offers superior corrosion resistance but is more expensive than carbon steel. Steel is easily weldable, allowing for complex and intricate designs.

Stainless Steel: As mentioned, stainless steel's primary advantage is its exceptional resistance to corrosion, making it ideal for outdoor applications or environments where moisture is prevalent. Stainless steel is also aesthetically pleasing, offering a clean and modern look. However, it is generally more expensive than carbon steel and can be more challenging to weld and fabricate. Different grades of stainless steel offer varying levels of corrosion resistance and strength, so it's essential to select the appropriate grade for the intended application.

Aluminum: Aluminum is a lightweight and corrosion-resistant metal that is often used for table bases where portability is a concern. Aluminum bases are typically less expensive than steel bases, but they are also less strong and durable. Aluminum is easily extruded and cast, allowing for complex shapes and designs. However, it is more susceptible to scratching and denting than steel and may not be suitable for heavy-duty applications. Aluminum is commonly anodized to provide a protective layer and enhance its appearance.

Cast Iron: Cast iron is a robust and durable material that is often used for traditional or vintage-style table bases. Cast iron bases are typically heavier than steel or aluminum bases and offer excellent stability. Cast iron is more brittle than steel and can be prone to cracking under impact. Cast iron is typically painted or powder coated to protect it from rust. The characteristic texture and weight of cast iron contribute to its unique aesthetic appeal. However, care should be taken to avoid dropping heavy objects on cast iron bases, as they can be damaged.

Wrought Iron: Wrought iron bases are known for their decorative and ornate designs. Wrought iron is a strong and durable material that can be shaped into intricate patterns. Wrought iron is typically more expensive than steel or aluminum and requires specialized fabrication techniques. Wrought iron bases are often used for outdoor furniture or in spaces where a traditional or rustic aesthetic is desired. Like cast iron, wrought iron is susceptible to rust and requires regular maintenance to prevent corrosion. Periodic painting or sealing is recommended to protect the metal from the elements.

Factors to Consider When Choosing a Metal Table Base

Selecting the correct metal table base involves considering several crucial factors to ensure optimal performance, durability, and aesthetic appeal.

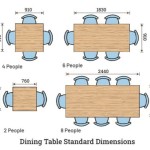

Table Top Material and Weight: The material and weight of the table top directly influence the required strength and stability of the base. Heavier table tops, such as those made from solid wood or stone, necessitate a more robust base than lighter table tops made from laminate or glass. The dimensions of the table top also play a role; larger table tops require a wider base to prevent tipping and ensure adequate support.

Intended Use and Environment: The intended use of the table and the environment in which it will be placed should be considered. Outdoor tables require bases made from corrosion-resistant materials, such as stainless steel or aluminum. Tables used in high-traffic areas require more durable bases that can withstand wear and tear. The height of the table should also be appropriate for its intended use. Dining tables typically have a height of 28-30 inches, while coffee tables are typically 16-18 inches high. Counter height tables and bar height tables will obviously need taller bases.

Style and Aesthetics: The style and aesthetics of the table base should complement the overall design of the room or space. Metal bases are available in various styles, from sleek and modern to ornate and traditional. The finish of the base should also be considered. Powder coating provides a durable and scratch-resistant finish, while plating offers a more decorative and luxurious look. The color of the base can also be customized to match the table top or other furniture in the room.

Stability and Load Capacity: The stability and load capacity of the table base are critical for ensuring safety and preventing accidents. The base should be able to support the weight of the table top and any items that will be placed on it. The base should also be stable enough to prevent tipping or wobbling. It's important to check the manufacturer's specifications for the load capacity of the base before purchasing it. For tables that will be used in public spaces, it's essential to comply with relevant safety standards and regulations.

Budget: The budget is always a factor in any purchasing decision. Metal table bases range in price from relatively inexpensive to very expensive, depending on the material, design, and quality. It's important to set a budget before shopping for a table base and to compare prices from different vendors. While it's tempting to opt for the cheapest option, it's essential to consider the long-term cost of ownership. A higher-quality base may cost more upfront, but it will likely last longer and require less maintenance. Furthermore, a sturdier base contributes to the longevity of the table top itself.

In conclusion, selecting the appropriate metal base for a table requires a comprehensive evaluation of the table's intended use, design aesthetics, and structural requirements. By carefully considering the various types of metal bases, materials and the key factors outlined above, one can ensure that the chosen base provides optimal stability, durability, and visual appeal for years to come.

Modern Metal Table Base For Square Or Round Top Dining Spider Steel

Twisted Metal Table Legs Heavy Duty Bases

Metal Square Coffee Table Base For 48 Inch Marble Glass And Wood Tables

Diy Metal Base Coffee Table Almost Makes Perfect

Custom Metal Table Bases Creative Design

Table Bases Custom Metal Home

Trapezoid Metal Coffee Table Base Steel Legs For Center Tables Old West Iron

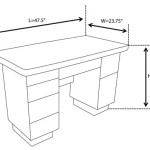

Gold Table Base 50 X 22 H28 310 Hoshi Handmade For Desk Kitchen Dining Stainless Steel Furniture Legs Flowyline Design

Vienna Metal Base Dining Table Urban Woods Beyond Sustainable Furniture

Custom Metal Table Bases Creative Design