The Enduring Appeal of a Pallet Dining Room Table

The pallet dining room table has emerged as a popular choice for homeowners seeking a unique and sustainable furniture option. The appeal stems from a combination of factors, including affordability, rustic aesthetics, and the possibility for customization. By repurposing discarded pallets, individuals can create a functional and stylish dining space centerpiece while simultaneously contributing to environmentally conscious practices. The creation of a pallet dining table involves a series of steps, from sourcing appropriate pallets to designing the table's dimensions and applying protective finishes. This article will explore the considerations and processes involved in constructing a pallet dining table, highlighting the benefits and challenges associated with this DIY furniture project.

The raw material for a pallet dining table is, of course, pallets. These are typically wooden structures used for transporting goods and can be found in various sizes and conditions. The selection of pallets is a critical first step. The ideal pallet should be structurally sound, free from significant damage, and ideally heat-treated rather than chemically treated. Heat treatment, often denoted by the "HT" stamp, indicates that the pallet has been subjected to a heating process to eliminate pests and pathogens, making it safer for indoor use. Chemical treatments, conversely, can leave harmful residues that may pose health risks. The type of wood used in the pallet can also influence the final appearance and durability of the table. Hardwoods, such as oak or maple, will naturally be more durable than softwood options.

Before beginning any construction, it is essential to thoroughly inspect and prepare the selected pallets. This involves removing any loose nails or staples, cleaning the wood to remove dirt and debris, and sanding the surfaces to create a smooth, even foundation. Depending on the desired aesthetic, the sanding process can range from a light smoothing to a more aggressive sanding to expose the wood grain fully. Safety should always be a primary consideration, requiring the use of appropriate personal protective equipment such as gloves, safety glasses, and a dust mask. Once the pallets are prepped, the design and construction can begin.

Design Considerations for a Pallet Dining Table

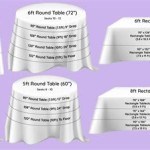

Designing a pallet dining table involves several crucial considerations. The size and shape of the table should be determined based on the available space and the number of people it needs to accommodate. Standard dining table heights typically range from 28 to 30 inches. This measurement should be factored into the design, considering the thickness of the pallets and any additional supports or legs that will be added to achieve the desired height. The layout of the pallets can vary significantly, ranging from a simple, single-pallet tabletop to a more complex arrangement involving multiple pallets joined together.

One common design involves using three pallets: two stacked to create the tabletop and one disassembled to provide wood for additional support and decorative elements. The design should also consider the aesthetic impact of the pallet's original markings and stamps. Some individuals prefer to retain these features to highlight the pallet's history and character, while others prefer to remove them or cover them up for a cleaner look. The choice of finish, such as stain, paint, or sealant, further influences the table's final appearance and durability. The design phase is also the appropriate time to determine if any additions will be needed, such as building a base out of metal legs or attaching decorative hardware.

The structural integrity of the table is another key design consideration. Pallets are often not designed to withstand significant weight concentrated in the center of the table. Reinforcing the table with additional supports, such as crossbeams or aprons, is essential to prevent sagging or instability. The type of fasteners used to join the pallets together also plays a crucial role in the table's strength. Screws are generally preferred over nails for their superior holding power. Furthermore, using wood glue in conjunction with screws can significantly enhance the joint's strength and durability. A well-engineered pallet dining table will not only be aesthetically pleasing but also able to withstand the rigors of everyday use. The complexity of the design can also be impacted by the tools and skills available to the builder. Simple designs are more conducive to being completed by those with fewer tools or less experience.

Construction Techniques and Assembly

The construction phase involves cutting, shaping, and joining the pallets according to the chosen design. This typically requires the use of a variety of power tools, including a circular saw, jigsaw, drill, and sander. Accurate measurements and precise cuts are essential to ensure that the table is level and stable. When disassembling pallets, it is crucial to exercise caution to avoid splitting the wood or damaging the surrounding structures. A reciprocating saw or a specialized pallet disassembly tool can be useful for this task. Once the individual pallet components are prepared, they can be joined together to form the tabletop and any supporting structures.

Joining the pallets together requires careful alignment and secure fastening. Wood glue should be applied to all mating surfaces to create a strong bond. Screws should be driven at appropriate angles to maximize their holding power. Clamps can be used to hold the pieces together while the glue dries and the screws are tightened. Reinforcing the joints with metal brackets or corner braces can further enhance the table's stability. When constructing the table legs or base, it is essential to ensure that they are level and securely attached to the tabletop. Adjustable feet can be added to compensate for any unevenness in the floor.

The construction process can be streamlined by creating templates or jigs to guide the cutting and assembly of the pallet components. This can improve accuracy and efficiency, especially when working with multiple pallets. It's also important to remember that variations in pallet dimensions are common. Careful measurement and compensation might be necessary. Regular checks with a level and square are also recommended to ensure the table remains aligned and stable throughout the construction process. Safety precautions remain paramount during this stage. Power tools should only be used by those with proper training and experience, and appropriate personal protective equipment must be worn at all times.

Finishing and Protection for Pallet Tables

The finishing stage is crucial for enhancing the appearance and protecting the pallet dining table. This involves sanding the surfaces to a smooth finish, applying a stain or paint (if desired), and sealing the wood with a protective coating. The choice of finish depends on the desired aesthetic and the level of protection required. Stains can enhance the wood grain and add color, while paints can provide a more uniform and opaque finish. Sealants, such as polyurethane or varnish, provide a durable barrier against moisture, scratches, and stains.

Before applying any finish, it is essential to thoroughly clean the table and remove any dust or debris. The finish should be applied in thin, even coats, following the manufacturer's instructions. Multiple coats may be required to achieve the desired level of protection and appearance. Sanding lightly between coats can help to create a smoother finish. The sealant should be allowed to dry completely before the table is put into use. Applying a food-safe sealant is especially important for a dining table, as it will come into contact with food and beverages. The type of sealant should also be durable enough to withstand regular cleaning and exposure to spills.

Beyond the initial finishing, ongoing maintenance is essential to preserve the beauty and longevity of the pallet dining table. This includes regular cleaning with a damp cloth and the occasional application of furniture polish. Spills should be cleaned up promptly to prevent staining. If the table is exposed to direct sunlight, it may be necessary to apply a UV-resistant sealant to prevent fading. With proper care and maintenance, a pallet dining table can provide years of enjoyment and serve as a unique and sustainable centerpiece for any dining room. The correct application of these finishing and protection techniques ensures that the rustic charm of the pallet wood is preserved while guaranteeing that the table is resistant to daily wear and tear.

Pallet Dining Room Table Lone Star Farmstead

Wood Pallet Table Diy A Beautiful Mess

40 Amazing Diy Pallet Furniture Ideas Bored Art Dining Table Projects

Pallet Kitchen Table For Your Dining Area Diy

Our Pallet Wood Dining Room Table

One Of A Kind Pallet Wood Project

Pallet Table Diy

13 Easy And Cost Effective Diy Pallet Dining Tables Shelterness

25 Pallet Dining Tables That Inspire Your Crafting Digsdigs

Diy Pallet Wood Dining Table Jenron Designs