Transforming Tables: The Versatility of Table Legs with Casters

Table legs with casters represent a convergence of functionality and adaptability in furniture design. They provide a simple yet effective method of transforming static tables into mobile units. This mobility enhances convenience in a variety of settings, from residential spaces to industrial environments. The addition of casters to table legs introduces dynamic flexibility, allowing for easy repositioning and reconfiguration of layouts without the need for heavy lifting or disassembly.

The demand for furniture that can adapt to changing needs has driven innovation in caster design and attachment methods. Modern table legs with casters are available in a wide array of styles, materials, and load capacities. This allows them to seamlessly integrate into diverse aesthetic preferences and functional requirements. Understanding the nuances of these components becomes crucial when choosing the right table legs with casters for a specific application.

The fundamental concept behind table legs with casters is to provide a mobile base for a tabletop. This is achieved by replacing traditional fixed table legs with legs that incorporate swivel casters at their base. The casters, typically made of materials like polyurethane, rubber, or nylon, allow for smooth, multidirectional movement. They facilitate moving the table across various floor surfaces with relative ease.

The attachment method for casters to the table legs varies depending on the design. Some legs feature threaded stems that screw directly into the caster housing. Others utilize a mounting plate that is bolted or screwed onto the leg. The choice of attachment method depends on factors such as the weight capacity of the table, the material of the leg, and the desired aesthetic.

The materials used in the construction of table legs with casters also play a significant role in their overall performance and durability. Steel legs offer robust strength and can withstand heavy loads, making them suitable for industrial or commercial applications. Aluminum legs offer a lighter weight alternative with good corrosion resistance. Wood legs provide a more traditional aesthetic and can be stained or painted to match existing décor. The caster housing itself is typically made of metal or reinforced plastic to ensure durability and smooth swivel action.

Key Considerations When Selecting Table Legs with Casters

Choosing the appropriate table legs with casters requires careful consideration of several factors. Weight capacity, caster type, and locking mechanisms are among the most important. Ignoring these factors can lead to instability, premature wear, and potential safety hazards.

Weight Capacity and Load Distribution

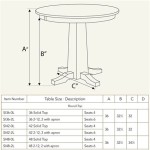

Weight capacity is a critical factor when choosing table legs with casters. Exceeding the weight limit of the casters can lead to premature failure, making the table difficult to move and potentially causing damage to the floor. The total weight that the table will bear, including the tabletop itself and any items that will be placed on it, must be accurately estimated.

The weight capacity is usually specified per caster. Multiplying this value by the number of casters (typically four) yields the total weight capacity of the table legs. However, it's essential to consider that weight distribution may not always be perfectly even across all four casters. Therefore, it's advisable to choose casters with a weight capacity that exceeds the estimated load by a safety margin of at least 20%.

The material of the table legs themselves must also be strong enough to support the anticipated load. A lightweight tabletop mounted on heavy-duty casters attached to flimsy legs is an unbalanced configuration. The legs could buckle or break under stress, rendering the entire assembly unusable. Selecting legs that are constructed from durable materials like steel or reinforced hardwood is important, particularly for tables that will bear significant weight.

Caster Type and Floor Surface Compatibility

The type of caster selected must be compatible with the floor surface on which the table will be used. Different caster materials offer varying levels of grip, durability, and resistance to wear. Selecting the wrong caster type can lead to floor damage, noisy operation, and difficulty in maneuvering the table.

Hard casters, such as those made of steel or nylon, are suitable for hard, smooth surfaces like concrete or tile. They offer low rolling resistance and are easy to clean. However, they can be noisy on uneven surfaces and may scratch or damage softer flooring materials like wood or vinyl.

Soft casters, such as those made of rubber or polyurethane, are better suited for softer floor surfaces like wood, laminate, or carpet. They offer better grip and are less likely to damage the floor. They also tend to be quieter than hard casters. However, soft casters may have higher rolling resistance and can pick up dirt and debris more easily.

For applications where the table will be used on a variety of floor surfaces, swivel casters with a dual-wheel design are often a good choice. These casters provide good stability and maneuverability on both hard and soft surfaces. They also tend to distribute the weight more evenly, reducing the risk of floor damage.

Locking Mechanisms and Stability

Locking mechanisms are an essential feature for table legs with casters, especially when the table needs to remain stationary for extended periods. Without a locking mechanism, the table may roll unintentionally, posing a safety hazard or disrupting work activities. Various types of locking mechanisms are available, each offering different levels of security and ease of use.

Side-locking casters are the most common type of locking mechanism. They feature a lever or pedal that engages a brake against the wheel, preventing it from rotating. Side-locking casters are relatively inexpensive and easy to operate. However, they may not provide the most secure hold, especially on uneven surfaces.

Total-locking casters provide a more secure hold by locking both the wheel and the swivel mechanism. This prevents the table from rolling or swiveling, providing maximum stability. Total-locking casters are often used in applications where safety is paramount, such as in hospitals or laboratories.

Directional-locking casters allow the table to be moved in a straight line but prevent it from swiveling. This can be useful for applications where the table needs to be moved down a hallway or across a large room. Directional-locking casters can also be used to keep the table from rolling away when it is parked on a slope.

Applications of Table Legs with Casters

The versatility of table legs with casters makes them suitable for a wide range of applications across various industries and environments. From enhancing flexibility in office spaces to providing mobility in healthcare settings, the benefits are demonstrable.

Office Environments

In modern office environments, flexibility and adaptability are highly valued. Table legs with casters allow for easy reconfiguration of workspaces to accommodate changing team sizes, project needs, or collaboration styles. Tables can be quickly moved from individual workstations to group meeting areas, promoting collaboration and efficient use of space.

Mobile training tables are particularly useful in corporate training rooms. They can be easily arranged in different configurations to suit various training formats, such as lectures, group discussions, or hands-on workshops. After the training session, the tables can be quickly moved and stored away, freeing up the room for other uses.

Height-adjustable tables with casters are becoming increasingly popular in offices as a way to promote employee health and well-being. Employees can easily adjust the height of the table to work comfortably while sitting or standing, reducing the risk of back pain and other musculoskeletal problems. The casters allow the table to be easily moved to different locations, providing employees with the flexibility to work in different areas of the office.

Healthcare Settings

In healthcare settings, mobility and hygiene are of paramount importance. Table legs with casters allow for easy movement of medical equipment, patient tables, and other essential items. This facilitates efficient patient care, reduces the risk of injury to staff, and allows for thorough cleaning and disinfection of surfaces.

Mobile instrument tables are commonly used in operating rooms and examination rooms. They provide a convenient and accessible surface for holding surgical instruments, medications, and other supplies. The casters allow the table to be easily moved to different locations as needed during procedures.

Overbed tables with casters are an essential piece of furniture in hospitals and nursing homes. They provide patients with a convenient surface for eating, reading, or working while they are confined to bed. The casters allow the table to be easily moved out of the way when not in use.

Industrial Environments

In industrial environments, durability and load capacity are crucial considerations. Table legs with casters allow for easy movement of heavy equipment, tools, and materials. This improves efficiency, reduces the risk of injury to workers, and allows for flexible use of space.

Mobile workbenches are commonly used in factories and workshops. They provide a stable and portable surface for assembling products, repairing equipment, or performing other tasks. The casters allow the workbench to be easily moved to different locations as needed.

Heavy-duty carts with casters are used to transport materials and equipment throughout the factory or warehouse. They can be customized with shelves, drawers, or other features to suit specific needs. The casters allow the cart to be easily moved, even when fully loaded.

Maintaining and Caring for Table Legs with Casters

Proper maintenance and care are essential for prolonging the lifespan of table legs with casters and ensuring their continued performance. Regular cleaning, lubrication, and inspection can help prevent premature wear and tear and maintain smooth, reliable operation.

Cleaning and Lubrication

Regular cleaning is essential for removing dirt, dust, and debris that can accumulate on the casters and table legs. A mild soap and water solution can be used to clean the surfaces. A soft brush or cloth can be used to remove stubborn dirt. Avoid using harsh chemicals or abrasive cleaners, as these can damage the finish.

Lubrication is important for maintaining smooth swivel action and preventing rust or corrosion. A silicone-based lubricant can be applied to the swivel mechanism and wheel bearings. Avoid using oil-based lubricants, as these can attract dirt and debris. The frequency of lubrication will depend on the frequency of use and the environment in which the table is used.

Inspection and Replacement

Regular inspection is important for identifying any signs of wear or damage. Check the casters for cracks, chips, or other damage. Also, examine the table legs for loose screws, rust, or other signs of deterioration. If any damage is found, the affected components should be replaced immediately.

The lifespan of table legs with casters will depend on the quality of the components, the frequency of use, and the environment in which they are used. However, with proper maintenance and care, they can provide years of reliable service.

Legs With Wheels And 4 Brakes Rustic Table Locking Mechanisms Coffee Industrial Dining

Regency 34 Galvanized Steel Legs With Casters For Work Tables 4 Set

Table Legs With Casters Wheels Industrial Metal Desk Diy

Kee Post Table Leg With Casters Set Of 4 Black Com

Diy Industrial Metal Table Legs Casters Bar Stools

Workpro Flex Collection Steel Arc Legs Lockable Casters Silver Set Of 2 Office Depot

Mobile Style Work Bench Legs Leg Adjustable H3036 3642 In 1 Increments Size W X H 36 35 Caster Type 2 Stationary 5 Rubber Casters Cap Lbs 700

Rumba 60x24 Fixed Base Table Post Leg Caster Safco S

Adjustable T Leg With Locking Caster Wheels Table Frame Goldstar Tool

Metal Table Base Wheels Legs Heavy Duty Handmade In Usa

Related Posts