Wood Table Base Ideas: DIY Plans for Every Style

A wood table base is a crucial element in defining the overall aesthetic and functionality of a table. Choosing or constructing the right base can significantly impact the table's stability, visual appeal, and integration into a specific room design. DIY wood table base projects offer an opportunity to create a customized piece that perfectly aligns with individual preferences and spatial requirements. This article will explore various wood table base ideas, providing comprehensive plans and considerations for successful implementation.

The decision to undertake a DIY wood table base project often stems from a desire for customization, cost-effectiveness, or the satisfaction of crafting a unique piece of furniture. Pre-fabricated table bases can be limiting in terms of size, style, and material selection. By opting for a DIY approach, individuals gain complete control over these aspects, allowing them to tailor the table base to their exact specifications. This flexibility is particularly valuable when working with unconventional table tops or attempting to match existing décor.

Before embarking on any DIY project, careful planning is essential. This involves determining the desired style of the table base, selecting appropriate materials, and creating detailed plans that account for structural integrity and aesthetic considerations. A well-defined plan minimizes errors, reduces material waste, and ensures a more efficient and enjoyable building process.

Choosing the Right Wood for Your Table Base

The selection of wood is a fundamental aspect of any wood table base project. Different wood species offer varying levels of strength, durability, workability, and visual appeal. Hardwoods, such as oak, maple, walnut, and cherry, are generally preferred for table bases due to their superior strength and resistance to wear and tear. Softwoods, such as pine and fir, are more affordable and easier to work with but may require additional reinforcement or protective finishes to ensure long-term durability.

Oak is a popular choice due to its strength, durability, and distinctive grain pattern. It is readily available and relatively affordable, making it a practical option for a wide range of table base designs. Maple is another excellent hardwood option, known for its smooth, even grain and exceptional hardness. It can be stained or painted to match any décor.

Walnut is a premium hardwood prized for its rich, dark color and beautiful grain. It adds a touch of elegance and sophistication to any table base. Cherry is another attractive hardwood with a warm reddish-brown hue that deepens over time. It is known for its stability and workability.

When selecting wood, it is crucial to consider its moisture content. Wood that is too wet or too dry can warp or crack over time, compromising the structural integrity of the table base. Kiln-dried wood is recommended, as it has been properly dried to a stable moisture content.

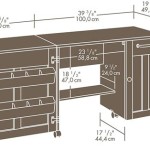

In addition to the type of wood, the dimensions of the lumber are also critical. The thickness and width of the wood will determine the strength and stability of the table base. For larger tables, thicker lumber is recommended to provide adequate support.

DIY Wood Table Base Plans: Design Ideas and Instructions

There are numerous DIY wood table base designs to choose from, ranging from simple and minimalist to intricate and ornate. The choice of design will depend on the desired aesthetic, the size and shape of the table top, and the skill level of the builder. Here are a few popular DIY wood table base plans, along with detailed instructions:

1. Simple A-Frame Table Base: This is a straightforward and sturdy design that is suitable for beginners. It consists of two A-shaped frames connected by a central stretcher. The frames can be constructed from 2x4s or 4x4s, depending on the desired size and strength of the table base.

To construct an A-frame table base, first cut the lumber to the desired length. The two legs of each A-frame should be angled at the top to form a peak. Join the legs together using screws and wood glue. Reinforce the joint with mortise and tenon joinery or metal brackets for added strength.

Once the A-frames are assembled, connect them with a central stretcher. The stretcher can be a simple 2x4 or a more decorative piece of lumber. Attach the stretcher to the A-frames using screws and wood glue. Ensure that the stretcher is level and securely fastened.

Finally, attach the table top to the A-frame base. This can be done using screws, bolts, or metal brackets. Ensure that the table top is centered on the base and securely fastened.

2. Industrial Pipe Table Base: This design combines the rustic charm of wood with the industrial aesthetic of metal pipes. It is a popular choice for modern and contemporary spaces.

To construct an industrial pipe table base, first gather the necessary materials, including wood for the table top and flanges, pipes, and fittings for the base. The size and shape of the pipes and fittings will depend on the desired design.

Start by assembling the pipe base. Connect the flanges, pipes, and fittings to create a sturdy and stable structure. Use pipe wrenches to tighten the connections securely. Apply pipe joint compound to the threads to prevent leaks.

Once the pipe base is assembled, attach it to the underside of the wood table top. This can be done using screws or bolts. Ensure that the base is centered on the table top and securely fastened.

The pipe base can be painted or left with its natural finish. A clear coat of sealant can be applied to protect the metal from rust and corrosion.

3. Trestle Table Base: A trestle table base is a classic design that provides ample legroom and a timeless aesthetic. It consists of two trestle supports connected by a stretcher.

To construct a trestle table base, first cut the lumber to the desired length. The trestle supports can be constructed from 4x4s or 6x6s, depending on the size and strength of the table. The stretcher can be a simple 2x4 or a more decorative timber.

Shape the trestle supports to the desired design. This may involve tapering the legs or adding decorative curves. Join the trestle supports together using mortise and tenon joinery or metal brackets.

Once the trestle supports are assembled, connect them with a stretcher. The stretcher should be positioned at the bottom of the trestle supports and securely fastened using screws and wood glue. Reinforce the joint with mortise and tenon joinery or metal brackets.

Attach the table top to the trestle base using screws, bolts, or metal brackets. Ensure that the table top is centered on the base and securely fastened.

Ensuring Stability and Structural Integrity

Stability and structural integrity are paramount when constructing a wood table base. A wobbly or unstable table is not only frustrating but also potentially dangerous. Several factors contribute to the stability of a table base, including the design, materials, and construction techniques.

The design of the table base should distribute weight evenly and provide a wide footprint. A-frame bases and trestle bases are inherently stable due to their wide stance. Avoid designs with narrow or unstable legs.

The materials used in the construction of the table base should be strong and durable. Hardwoods are generally preferred over softwoods for their superior strength. The dimensions of the lumber should also be adequate to support the weight of the table top and any objects placed on it.

The construction techniques used to assemble the table base should be precise and robust. Joints should be tight and secure, using a combination of screws, wood glue, and reinforcing elements such as mortise and tenon joinery or metal brackets. Avoid using nails, as they do not provide sufficient holding power for structural applications.

Consider adding cross braces or stretchers to the table base to increase its stability. These elements help to prevent racking and twisting, which can lead to wobbling. Ensure that all connections are tight and secure.

Leveling the table base is also essential for ensuring stability. Use shims or adjustable feet to compensate for uneven floors. A level table will be much more stable and enjoyable to use.

Properly finishing the wood table base is also crucial for protecting it from moisture, scratches, and other damage. Apply a durable finish such as polyurethane or lacquer to seal the wood and provide a protective barrier. Regularly maintain the finish to prevent it from deteriorating over time.

How To Build A Farmhouse Table

Outdoor Table With X Leg And Herringbone Top Free Plans

Creative Diy Table Legs For Fab Custom Furniture Girl In The Garage

X Leg Coffee Table Diy Montreal

Heavy Duty Wooden Table Leg Ideas

Diy Wood Slat Table Base And How I Treat All My Pine Banyan Bridges

Folding Table Base Plan Craft Compact Diy Wood Pattern

How To Build A Farmhouse Dining Table Part 1 Design Top

If You Give Your Mom Some Built Ins She S Going To Want A Table Too Diy X Base Dining

The Project Lady How To Build A Farmhouse Table Post 3 Making Aprons